Mouchot's sun engine

The Mouchot solar engine was ahead of it's time

History

The utilization of the rays of the sun as a motor is by no means a novel idea; we will not say it is as old as the sun itself, but very early attempts have been made to convert the heat engendered by them into a substitute for fuel. Euclid, Archimedes, Hero of Alexandria, Solomon de Caus, Buffon, De Saussure, Ducarla, Pouillet, Franchot, Ericsson, and others, have added the results of their researches to the solution of the question in time past.

In 1868 Ericsson published analogous experiences in Philadelphia; but M. Mouchot, the wellknown French savant, whose efforts commenced in 1861, has gone further than any one else in reducing the problem to a practical form in the large engine he exhibited near the aquarium in the Trocadero grounds.

In 1861 Mouchot patented an invention which he named "Heliopompe", and in 1865 he had several small engines of this description at work at Tours, Indre-et-Loire. As a distinction of construction, M. Mouchot avoided the use of parabolic mirrors and added a glass jacket to retain the heat.

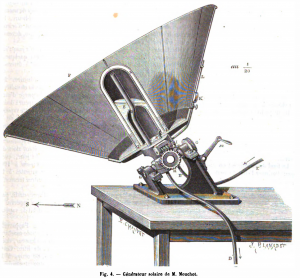

The engraving below will give a general idea of the principle of construction and the mode by which the rays of the sun are collected and utilized.

Engine Arrangement

The solar generator is shown in fig. 4. The mirror has the shape of a truncated cone with parallel bases, like a lampshade, turning its opening towards the sun. The generator of this truncated cone makes an angle of 45 degrees with the axis; it is the best shape we can give to these kinds of mirrors, because the incident rays parallel to the axis are then normally reflected on this axis, and give a focus of maximum intensity for the same or mirror texture.

The reflecting wall is made up of twelve sectors, in silver plated, supported by an iron frame in which they slide side by side. This arrangement makes it possible to remove each sector for cleaning and, consequently, to replace the silver plate with polished brass which produces the same effect. The opening diameter of the mirror is 2.6 m; that of the bottom is 1 m, from which it follows that the normal insolation surface of the device is 4 m2.

The bottom of the mirror is a cast iron disc adjusted to reduce the effect of the wind. At the center of this is the boiler, whose height is that of the mirror. It is made of copper, blackened on the outside, and consists of two concentric envelopes, in the shape of a cloche, connected at their base by an iron flange.

The largest envelope is 80 cm high, the smallest 50 cm; their respective diameters are 28 and 22 centimeters. The feed water is housed between these two envelopes, so as to form an annular cylinder 5 centimeters thick. The volume of the liquid should hardly exceed 20 liters, in order to leave about 10 liters for the steam chamber.

The internal envelope remains empty; it is terminated by a copper tube which opens on one side into the vapor chamber, and communicates, on the other side, by mean of a flexible pipe, with the engine. A second flexible hose, starting from the bottom of the boiler, is used for the supply of water. Finally, safety devices are attached to the steam pipe.

As for the glass envelope, it is a cloche of 85 centimeters high, 40 centimeters in diameter and 5 millimeters thick. It therefore leaves a constant gap of 5 centimeters between its walls and those of the boiler, and is only adherent by its foot to the bottom of the mirror.

Operation

The generator must rotate 15 degrees per hour, around a shaft parallel to the axis of the world, and gradually tilt on this shaft with regard to the declination of the sun.

To achieve this double goal, the device is supported by gudgeons on a shaft perpendicular to their axis, and this shaft forms, from north to south, with the horizon, an angle equal to the latitude of the place. From this result two movements, which allow the generator to follow the course of the sun, whatever the apparent position of the latter. These two movements are each carried out by means of a open screw and require only a crank stroke, the first from half an hour to half an hour, the second every eight days. The movement from east to west can even, without spending too much, become automatic.

The device described here has worked under the sun of Tours, France.

Here are some of the results it has given when measured at various times.

On May 8th, in good ordinary weather, 20 liters of water at 20 degrees, were introduced into the boiler at 8 a.m. 50 m. morning. After purging the air, it took forty minutes to produce steam at two atmospheres, that is to say at 121 degrees. The steam then rose quickly to the pressure of 5 atmospheres, a limit which it would have been dangerous to cross, despite the regularity of heating, the walls of the boiler having only 5 millimeters of thickness and the total effort supported by these walls being already 40,000 kilograms.

Towards the middle of the day, with 15 liters of water in the boiler, the steam at 100 degrees rose in less than fifteen ninutes at the pressure of 5 atmospheres, or, in other words, at the temperature of 155 degrees.

On July 22, around 1 p.m. in the afternoon, in exceptional heat, the device vaporized 5 liters per hour, which corresponds to a steam flow of 140 liters per minute.

In the absence of a suitable machine for the device, Mr. Mouchot first used a large demonstration machine, without expansion or condenser, the pump body of which was a third of a liter. This machine was beating, in good weather, at 80 strokes per minute, under constant pressure from an effective atmosphere: it was still operating with a slightly veiled sun.

Most recently, he replaced it with a small Behrens rotary machine; it worked wonderfully and operated a lift pump at high speed, but which was too weak for the generator and eventually fell apart.

Finally, by simply conducting the steam of the device into a stove topped with a still he was able to distill 5 liters of wine in a quarter of an hour. This same steamer cooked quickly, and in abundance, vegetables, livestock feed, etc.

From the above results, we can conclude that this device uses on average, in our regions, from 8 to 10 calories per minute and per square meter. However this is only an approximation, because the impact of reflected heat always increases from the base to the top of the boiler. Therefore the temperature of the boiler is not uniform.

In this machine, plated blades were only a quarter of a millimeter thick and did not send all the incident heat to the boiler.

M. Mouchot concludes that this application of solar heat is of the greatest interest to the future of countries where the sky remains pure for a long time, and of which the sun is the most precious resource.