Ericsson's Caloric Engine of 1852

Source : Contributions to the Centennial Exhibition, Chap XXX, p. 425

Title: The Caloric Engine. Application of heated Air as a Motor.

Author: John Ericsson

Date: 1876

Engineers are aware that I built a caloric engine in London, 1833, operated by heated atmospheric air; Faraday, Ure, and Lardner taking great interest in the same in consequence of its being based on the principle of returning, at each stroke of the working piston, the heat not converted into mechanical work during the previous stroke.

After my arrival in this country (USA), 1839, I prosecuted the plan and built several caloric engines in succession, all of which promised ultimate success.

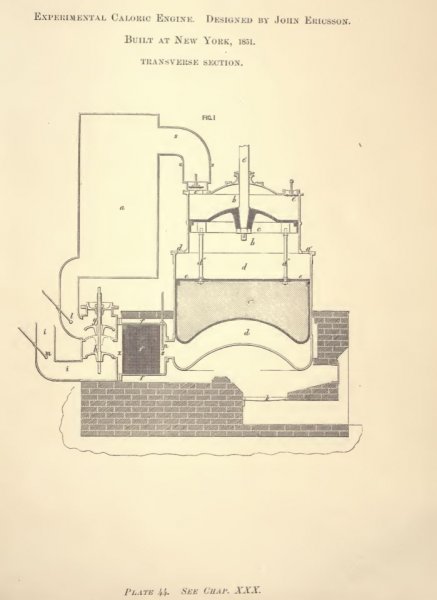

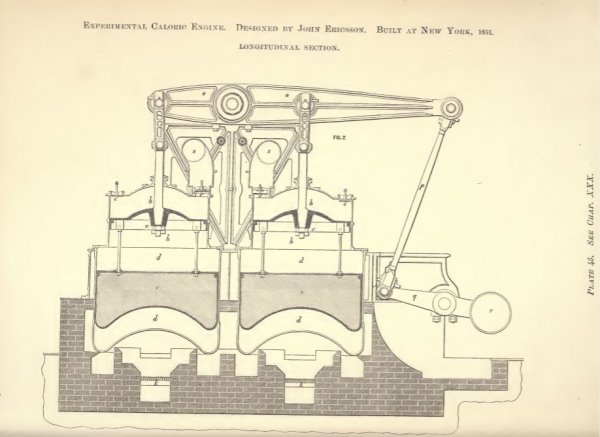

At each step the dimensions were enlarged, until I produced an experimental engine, in 1851, having two working cylinders of seventy-two inches diameter, two feet stroke, and two compressing cylinders of fifty-eight inches diameter (see illustrations on Plates 44 and 45).

The leading feature of this large caloric engine was that of circulating the heated air, as it passed off from the working cylinder, through a series of wire discs containing an aggregate of 13,520,000 meshes for each working cylinder.

The cold air in entering the engine was admitted through the meshes of the heated discs, taking up nearly the whole of the heat previously imparted by the exhaust air in its passage through the meshes, on its way to the atmosphere.

The Caloric Engine description

Description of the illustrations referred to (Copied from Appleton's Magazine of 1853)

Fig. 1 represents a transverse section, and Fig. 2 a longitudinal section of the engine.

a, air-receiver,

b b, supply-cylinder,

e', self-acting valve for letting air into, and e'' self-acting valve for letting air out of, the same.

c, supply-piston ;

c', piston-rod of the same, connected to the working-beam of the engine.

d d, working-cylinder ;

d' d', holes at the junction of the two cylinders, through which the atmospheric air passes in and out freely.

e e, working-piston ;

d'' d'', rods connecting the two pistons together,

e''', air-tight vessel, suspended below the workingpiston, filled with clay and charcoal to prevent transmission of heat from below,

f f, regenerator ;

f', discs of wire-net, placed vertically in the regenerator-box,

g, valve, worked by the engine, for admitting air into the regenerator and working-cylinder;

k, valve for letting air out of the same.

i i, pipe, open to the atmosphere, for carrying off the air after having passed through the engine;

k, fire-place.

The Caloric Engine Operation

The operation of the engine is briefly as follows : a slow fire being kept up at k for about two hours, until the various parts contained within the brick-work shall have become moderately heated, the air-receiver is charged by means of a hand-pump.

As soon as the internal pressure shall have reached about six pounds to the square inch - invariably effected in less than two minutes - the hand-pump is stopped, and the valve g opened by a starting lever, as in steam-engines; the compressed air from the receiver, thus admitted under the valve g, rushes through the partially heated wires f' into the working-cylinder, forcing its piston e upwards, as also the supply-piston c, by means of the connecting-rods d'' d''.

The atmospheric air contained in the upper part of cylinder b will, by this upward movement of the supply-piston, be forced through the valve e'' into the air-receiver.

When the working-piston has reached three fourths of the full stroke, the valve g is closed by the engine ; and when the piston has arrived at the full up-stroke, the valve h is opened.

A free communication with the atmosphere being thereby established by means of the open pipe i i, the air under the working-piston passes off, and, owing to the removal of pressure under the working-piston, it will instantly begin to descend by its own weight.

The heated air from under the working-piston, in passing off through the wires f', gives out its caloric to the same so effectually that, on reaching the thermometer m, the temperature never exceeds that of the entering air at l by more than 30°; on the other hand, the cold air from the receiver, in circulating through the meshes of wires in its passage to the working cylinder, becomes so effectually heated that, on passing n, its temperature is invariably increased to upwards of 450° when the machine is in full operation.

It is evident that during the descent of the supply-piston c the outlet valve e'' remains closed by the pressure from the receiver, whilst the inlet valve e' is kept open by suction, and hence that a fresh quantity of atmospheric air enters the supply-cylinder at each down-stroke of its piston, and by the up-stroke is forced into the receiver.

There being two supply-cylinders of alternating action, a constant supply of fresh air into the receiver is obtained for feeding the working-cylinders.

It need hardly be stated that the smaller quantity obtained by the supply-cylinder suffices to fill the larger capacity of the working-cylinder, in consequence of the increase of volume attending the increase of temperature ; nor need it be stated that an equal amount of force is exerted by the up-and-down movement, as there are two pair's of cylinders attached at opposite ends of a common working beam.

The foregoing description being deemed sufficient to explain the mechanical operation of the engine, the result of its prolonged trial may now be considered ; but, before doing so, it will be well to state some particulars in relation to the regenerator.

The Regenerator

The regenerator measures 26 inches in height and width internally ; each disc of wire contains 676 superficial inches, and the net has 10 meshes to the inch; each superficial inch, therefore, contains 100 meshes, which, multiplied by 676, gives 67,600 meshes in each disc; 200 discs being employed, it follows that each regenerator contains 13,520,000 meshes, and, consequently, if we consider that there are as many small spaces between the discs as there are meshes, we shall find that the air within the regenerator is distributed in 27,000,000 minute cells.

Theory clearly indicates that, owing to the small capacity for heat of atmospheric air (that beneficial property which the Great Mechanician gives to it as a fit medium for animated warm beings to live in), and in consequence, also, of the almost infinite subdivision among the wires, the temperature of the circulating air, in passing through the regenerator of the caloric engine, must be greatly changed.

Practice has fully realized all that theory predicted, for the temperatures at x and z have never varied during the trials less than 350°, when the engine has been in full operation ; indeed, it has been found impossible to obtain a differential temperature of less magnitude, with sufficient fires in the furnaces.

The reason is evident : the cold air from the receiver is half the time playing upon the wire discs at x, whilst the heated air from the working-cylinder is playing during the other half on the wire discs at z ; as no heated air can reach the former without passing through the regenerator, and as no cold air can reach the discs at z before likewise passing all the wires, it follows that the establishing an equilibrium of temperature becomes impossible.

The great number of discs, their isolated character, and the before-named distribution of the air in such a vast number of minute cells, readily explain the surprising fall and increase of temperature of the opposite currents passing the regenerator, and which constitutes the grand feature of the caloric engine, effecting, as it does, such an extraordinary saving of fuel by rendering the caloric not converted into mechanical work active over and over again.

In further explanation of the wonderful efficiency of the regenerator, it may be stated that each disc contains 1,140 feet of wire in length, and each regenerator 228,000 feet, or 41.5 miles, of wire; the superficial measurement of which is 2,014 square feet, which is equal to the entire surface of four steam-boilers forty feet long and four feet diameter; and yet the regenerator displaying that amount of heating surface is only two feet cube, less than 1/1920 of the bulk of said boilers !

In regard to loss of heat, the result of ample trial has been that at no time has the temperature of the escaping air at m exceeded that of the entering air at l by more than 30°.

As this differential temperature exhibits the positive loss of heat, it becomes important to ascertain its amount in pounds of coal : the area of the supply-piston is 2,626 square inches, and its stroke two feet ; hence 36 4/10 cubic feet of atmospheric air is supplied for each stroke, and therefore at 30 strokes 1,092 cubic feet, and for both cylinders 2,184 cubic feet per minute = 131,040 cubic feet per hour.

The weight of atmospheric air is nearly 13.5 cubic feet to the pound, and hence it will be seen that 9,706 pounds of air pass through the engine every hour.

We know that one pound of coal will raise the temperature of 10 pounds of water 1,100°, while the specific heat of water is to that of the air as 26 : 100 ; hence it will be seen that 38 4/10 pounds of air will be elevated in temperature 1,100° with one pound of coal.

Now, the observed loss of heat in the engine being 30°, the fact will be established that the loss will amount to one pound of coal for every 1,408 pounds of air passed through the engine, which, on 9,706 pounds, proves the actual loss of heat in both regenerators to be only 6 3/10 pounds of coal per hour.

A pressure of 13 pounds being sustained in the receiver, exerting 60 horse-power with an actual waste of only 6.8 pounds per hour, it will be found that two ounces of coal per hour per horse-power is the quantity of fuel absolutely wasted in the process of transfer.

The actual consumption of the engine is, however, nearly 40 pounds per hour, which is thus proved by the foregoing to be chiefly carried off by radiation of heat. On a large scale much of that radiation will be prevented.

As the machine stands, an indicated horse-power is produced by a consumption of less than 11 ounces to the horse-power per hour.

The following particulars are of considerable practical importance :

1st. The valves g and h are not subjected to heat, the caloric being taken up by the wires before reaching the valves.

2d. The temperature of the packing of the working-pistons does not exceed boiling heat at any time, proving the efficacy of the heat-intercepter e'''.

3d. As only a slow radiating fire is needed, it has been found that common whitewash, applied to the under side of the heater, remains for several weeks, proving conclusively that the effect of the heat is quite harmless.

4th. A hole of half an inch diameter, kept open for several hours, in the valve-chest, under the inlet-valve g, does not sensibly affect the pressure in the receiver a, so abundant is the supply of air. This fact has surprised all practical men who have witnessed the operation of the engine. It proves completely that the machine need not be perfectly air-tight, as supposed by many.

5th. After putting a moderate quantity of fuel into the furnace, it has been found that the engine works with full power for three hours without fresh feed, and, after removing the fires entirely, it has frequently worked for one hour.

The Caloric Ship

The regularity of action and perfect working of every part of this experimental engine, and, above all, its apparent great economy of fuel, induced some enterprising merchants of New York, in the latter part of 1851, to accept my proposition to construct a ship for navigating the ocean propelled by paddle-wheels actuated by the caloric engine.

This work was commenced forthwith, and pushed with such vigor that within nine months from commencing the construction of the machinery, and within seven months from laying the keel, the paddle-wheels of the caloric ship Ericsson turned round at the dock !

In view of the fact that the engines consisted of four working-cylinders of 168 inches diameter, 6 feet and four air-compressing cylinders of 137 inches diameter, 6 feet stroke, it may be claimed that, in point of magnitude and rapidity of construction, the motive machinery of the caloric ship stands unrivalled in the annals of marine engineering.

It may be added that the principal engineers of New York all expressed the opinion that a better specimen of workmanship than that presented by the huge engines of the caloric ship had not been produced, by our artisans up to that time.

The following data, published in Appleton's Mechanic's Magazine, will interest the professional reader.

Dimensions of the Ericsson

- Length on deck: 260 feet

- Length of keel: 250 feet

- Breadth of beam: 40 feet

- Depth of hold: 27 feet

- Draught of water on trial-trip: 17 feet

- Diameter of wheels: 32 feet

- Length of bucket: 10.5 feet

- Breadth of bucket: 20 ins.

- Dip of wheel (supposed about): 2 feet.

Engines

- Number of working-cylinders or single-acting air-engines: 4

- Diameter: 168 inches

- Area of piston: 22167.07 sq. in.

- Stroke: 6 feet

- Portion of stroke from commencement at which air is "cut off" (about): 63/100

- Cubical contents of each working-cylinder: 1596024 cub. in.

- Cubical contents of 63/100 of working-cylinder: 995495 cub. in.

- Number of supply-cylinders or single-acting pumps: 4

- Diameter: 137 inches.

- Area of piston or plunger: 14741 sq. in.

- Stroke, necessarily: 6 feet.

- Cubical contents of each pump: 1061352 cub. in.

Regenerator

- Number of regenerators: 4

- Number of discs of iron-wire netting in each regenerator: 50

- Height of each disc: 6 feet.

- Width: 4 feet

- Size of wire: 1/16 inch

- Ratio of area of openings in the netting to total area of disc: 1/2 to 1

- Total area of opening of "air-way" through each disc 6 x 4 / 2 = 12 sq. ft

Cylinders and pistons

- Greatest or total heat of air in working cylinder above atmosphere: 384 F.

- Heat of issuing air above atmosphere: 30 F.

- Pressure necessary to move the engine: 1/2 lb.

- Coal consumed in the four furnaces per day: 6 tons.

- Maximum coal possible to consume in the four furnaces per day: 7 tons

- Number of smoke-pipes: 2

- Number of air-pipes: 2

- Height of each smoke and air pipe above deck: 12 feet

- Diameter: 30 inches

- Amount of air passing through the four cylinders per hour: 50 to 75 tons

- Depth of working-piston, or thickness: 6 feet

- Thickness of cylinder-bottom: 1.5 inch

- Distance of grate from bottom of cylinder,: 5 feet

Temperature, Pressure, Volume of Air, Revolutions, Power

- Ordinary pressure of the engine per sq. inch: 12 lbs.

- Actual pressure on the second trial-trip, January 11: 8 lbs.

- Number of revolutions under pressure of 8 lbs. on trial trip: 9

- Number of revolutions expected with 12 lbs. pressure: 12

- Miles per hour obtained on trial-trip, January 11, allowing for tide, etc.: 7

- Miles per hour expected with 12 lbs. pressure: 10 to 12

- Number of meshes in each disc: 500000

- Temperature in working-cylinder, 60 + 384 = 444°

- Common temperature of the atmosphere (usual assumption): 60°

- Specific heat of air water being 1000: 0.2669

- Common pressure of air per square inch 14.73 lbs., say: 15 lbs.

- Weight per cubic foot, common pressure and temperature = .0752914 lbs., say: 1/13 lbs.

- Density of air, temperature remaining constant, is directly as the pressure.

- Weight per cubic foot, at 12 lbs. pressure. common temperature: 27/195

- Expansion of air at 32° for each degree added, according to Rudberg: 1/493

- Dalton and Gay-Lussac, .00208 ; Regnault, 1/491 ; common estimate: 1/480

- Expansion of air at 60°, for the 384° added: 384/508

- Density of air at (60° + 384° =) 444°, compared with air at 60°, as: 508/(508 + 384) to 1

- Weight of a cubic foot at 12 lbs. pressure, temperature 444° = 508/892 x 27/195 = 13716/173840 lbs.

- Weight of 995495 cubic inches at 12 lbs. pressure, temperature 444° = 995495/1728 x 13716/173840 = 46 lbs.

- Therefore, air passed through each cylinder each stroke: 46 lbs.

- Weight of 1061352 cubic inches, at common temperature and pressure = 1061352/1728 x 1/13 = 47.153 lbs.

- Allowance made for clearance, leakage, etc., per stroke, 47 - 46 = 1 lb.

- Units of heat required to raise 47 lbs. air 384° = 47 X 384 X .2669 = 4817 units

- Units of heat retained by the 47 Ibs. on escaping = 47 X 30 X .2669 = 376 units

- Units of heat transferred each stroke: 4441 units

- Absolute theoretical consumption of heat per stroke, per cylinder: 376 Units

- Mean pressure, per square inch, on working piston, allowing for continued addition of heat while expanding, initial pressure being 13 lbs., about: 10.8 lbs.

- Mean force acting upon working-piston, 10.8 X 22167 = 239403 lbs.

- Mean resistance per square inch to supply piston, commencing with and increasing to 12 lbs., at which pressure it continues to end of stroke.

- (The mean resistance in compressing an elastic fluid may be found by reversing the ordinary calculation on expansive working. The hyp. log. of 15/27 if is .588) 1.588 X 12 X 15/27 = 10.55 lbs .

- Mean resistance against supply-piston 10.55 X 14741 = 15559 lbs.

- Balance tending to move the engine, 239403 - 155598 = 83805 lbs.

- Units of power theoretically obtainable per stroke = 83805 X 6 = 502830 units

- Units of power theoretically obtainable from each unit of heat: 1337

The ship after completion made a successful trip from New York to Washington and back during the winter season ; but the average speed at sea proving insufficient for commercial purposes, the owners, with regret, acceded to my proposition to remove the costly machinery, although it had proved perfect as a mechanical combination.

The resources of modern engineering having been exhausted in producing the motors of the caloric ship, the important question has for ever been set at rest : Can heated air as a mechanical motor compete on a large scale with steam ? The commercial world is indebted to American enterprise to New York enterprise for having settled a question of such vital importance. The marine engineer has thus been encouraged to renew his efforts to perfect the steam-engine, without fear of rivalry from a motor depending on the dilatation of atmospheric air by heat.

The engines of the caloric ship being an exact counterpart of the experimental engine of 1851, excepting dimensions, a description has been deemed superfluous. It may be mentioned, however, that the pair of engines in the caloric ship actuated a single crank in the middle of the paddle-shaft by connecting-rods working at right angles on a common crank-pin, as in all my marine engines.