Cayley's Hot Air Engine of 1837

Source: Minutes of Proceedings of the Institution of Civil Engineers, Vol IX, p. 194, n° 822

Title: Description of Sir George Cayley’s Hot-air Engine

Date: 1849

Author: William W. Poingdestre

Hot Air to replace Steam

The object of attempting to obtain an engine impelled by hot air, instead of steam, is the economy promised, by the difference in the specific heat of these two bodies.

According to the experiments of Lavoisier and Laplace, which have been since confirmed by Crawford, Dalton, and Count Rumford, it is shown, that the specific heat of water being I, that of an equal weight of air is 0.2669; therefore, if 1 lb. of fuel is sufficient to heat a given weight of water 1o, it will only require 0.2669 of a lb. to heat the same weight of air 1o, or about one-fourth of the former quantity.

It has also been proved, that when the temperature of air is increased 480o, its volume, or bulk, is doubled; or if this quantity is retained within the original space, its pressure will be double, giving an available power, above the atmosphere, of 15 lbs. per square inch.

Ericsson's Flame Engine

In a paper in the archives of the Institution by Lieutenant Ericson, a description is given of a mode which had been successfully employed, in Sweden, for using hot air, instead of steam, as a prime mover.

In this paper it is stated that “the heat evolved by combustion, has hitherto alone been employed as a moving power, by raising steam, without regard to the nature of the combustibles, and as the combustion has always been performed in open furnaces, it has seldom obtained that degree of vividness, which is found necessary for obtaining the greatest quantity of heat.”

One of the methods practiced by Mr. Ericson, was to burn fuels containing a large proportion of carbon, (consequently giving out great heat, but little flame,) in close vessels, supporting the combustion by means of air supplied by blast cylinders. The gases thus generated were then led either to a working cylinder, to act immediately upon the piston, by means of their expansive force, or into a steam boiler, to accelerate the evaporation, and increase the expansion of the steam, or into steam already generated, to mix with it in a separate vessel.

Mr. Ericson considered, that by using blast cylinders, the fuel generated more heat, and was more completely burnt, than in an open fire, and as there was no other issue, than through the working cylinder, little caloric was left.

In the year 1833, an engine, to be impelled by hot air, was made in England, for Mr. Ericson. In this case, he did not employ the products of combustion, in the manner above described, but used air, heated by transmission through a close chamber, similar to the arrangement for heating water to raise steam.

Cayley Hot Air Engine

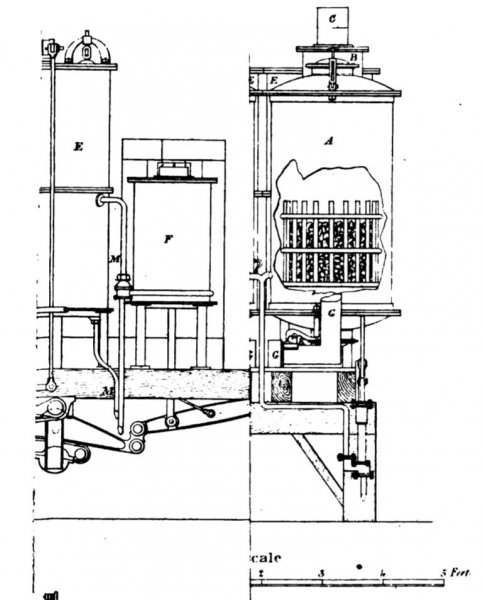

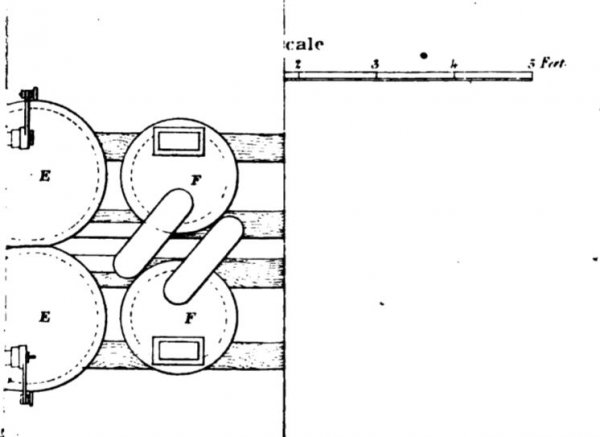

In 1837, Sir George Cayley, Bart., Assoc. Inst. C.E., applied the products of combustion from close furnaces, so that they should act directly upon a piston in a cylinder Plate No. 9 represents a pair of engines upon this principle, together equal to 8 HP, when the piston travels at the rate of 220 feet per minute.

A, A, are the close furnaces; B, B, the chambers, fitted with wire-gauge to keep back the cinders; C, C, the passages to the cylinders; D, D, the valves; E,E, the working cylinders; F, F, the air-pumps; G,G, the passages for the cold air; H, H, the pipes for injecting the water on to the fire; J, J, the expansion gearing; K, K, the safety-valves; L, L, he asbestos sights for looking at the fire; and M, M, the oil-pipes.

The engines are placed side by side, upon a base about 8 feet long by 4½ feet wide.

Each engine consists of a generator of heat, a working cylinder, and an air-pump, or blower; the air-pump is half the size of the cylinder, and blows air into and through a fire, enclosed within the generator. In the passage of the air through the fire, the oxygen serves to support the combustion, and the other gaseous bodies pass, at a temperature of about 600° Fahrenheit, laterally through a chamber, for separating the gaseous bodies from any ashes, or cinders, into the working cylinder, which is very similar in shape, valves, &c., to the cylinder of a single acting steam-engine.

The furnace is enclosed in the generator, and the fire is well got up, before the doors of the generator are closed, when a few jets of water are thrown upon the then close fire, and give the first impulse to the engine, causing the immediate action of the air-pump, which continues to work regularly; the fire is replenished by stopping the blast from the furnace, and opening the upper bonnet.

In this kind of engine, the great sensible heat has been found to destroy the valves, piston and cylinder, and likewise to carbonize the lubricating oil, so that there is great difficulty in keeping the working parts of the engine in order.

Mr. A. Gordon, M. Inst. C.E. has stated, that having examined Sir G. Cayley’s engine when working at Millbank, and having seen at work the engines of Mr. Stirling, and the last one of Mr. Ericson, he determined to attempt the propulsion of a boat, by the direct application of the products of combustion, (which rush out at the rate of 1,330 feet per second,) without the intervention of any machinery, between the furnace and the water to be acted upon by the hot blast.

His first experiment gave such promise of ultimate success, in this simple application of heated, and permanently elastic, aeriform bodies, that he determined to continue the investigation, but, at present, no account of further success has been made public.

The communication is accompanied by one drawing, No. 4493, from which Plate No. 9 has been compiled.

The Hot Air Engine as an imitation of the Steam Engine

Mr. A. Gordon said, that Sir George Cayley’s engine was a beautiful exhibition of the power of heat, when a permanently elastic fluid was used, instead of steam, and it exemplified the economy which must result, if permanently elastic bodies could be used instead of steam.

He considered, that there had been no fundamental improvement in the steam engine, since the time of James Watt, though engines were now constructed in a superior manner, and by enlarging the ports, and modifying other portions of the machine, some kinds of steam-engines were enabled to be worked faster. The beautiful arrangements of Watt for preserving heat in the easily-condensed steam, were not, however, required for hot air.

Almost every person who had attempted to apply either air heated by transmission, or the hot products of combustion from close furnaces, had adopted the ordinary form of the steam-engine though a hot-air engine differed from it essentially, the only similarity consisting in their both deriving their power from the action of heat. The manner of using the expansive action of the two bodies differed materially.

In attempting to introduce hot air, as a motive power, it was necessary to go back to the year 1681, - the days of Denys Papin, - and almost to copy his method of applying the hot products of combustion to the steam-engine, in its original state; then commencing at that point, and avoiding any imitation of the present steam-engine, an available application of the hot products of combustion form close furnaces, instead of steam, would be arrived at.

If Denys Papin had, in the year 1681, applied the hot products of combustion from close furnaces, instead of steam, to act on the surface of water in his working chamber, he would have been able to press down the surface of the water in the chamber, by such heated aerifrom bodies, which had not, like steam, the property of being condensed immediately, and the theoretical advantages of using permanently elastic fluids, instead of steam, would have been long since proved to be practically and commercially advantageous. Every imitation of the steam engine, had been a bar to the introduction of hot air, as a motive power.

Sir George Cayley, Mr. Stirling, and Captain Ericson, had merely applied the hot products of combustion, to a modification of the form of the steam engine, and although the former had succeeded in making a beautiful engine, it was not yet commercially satisfactory.

Another method to use the power of hot gases

Mr. Gordon viewed the question in another light, and he considered, whether the close furnace, and the hot products of combustion, rushing out at a temperature of 500°, and at the rate of 1,332 feet per second, could be made available as a motive power. The effect of discharging the hot products of combustion, from a close furnace, under and against the water, with the view to propel a boat, might be easily calculated.

Robison in his “Mechanical Philosophy” gave a formula, which might be used for calculating the effect of such an arrangement, as would, without the intervention of machinery between the close fires, and the water in which the boat floated, be similar, in its effect, to the combustion of a mild and continuous rocket.

Borda’s experiments on 81 inches, show that the impulse of the wind moving one foot per second, is about 1/506 of a pound on a square foot. Therefore, to find the impulse on a foot corresponding to any velocity, divide the square of the velocity by 500, and we obtain the impulse in pounds. (Robison’s Mechanical Philosophy, vol. III. p. 716).

It would always be necessary, in a hot-air engine, and in every application of hot air, to pump air into the furnace, by which half of the power generated would be consumed. Sir George Cayley had been perfectly successful in that respect, and Mr. Gordon believed the day would ultimately arrive, when, by surrounding the close furnaces with water, a small engine would be driven by steam so raised, and which would also supply the close fire, and give that rapid current of hot air, even now available, without the intervention of any machinery between the fire and the water.

Cayley's Experiments

Mr. Goldsworthy Gurney said, that in 1825, Sir George Cayley directed his attention to the laws of expansion of aeriform bodies, and pointed out the advantage of using them, as an economical agent for obtaining power. An interesting paper on this subject was published by Sir George Cayley, in Nicholson’s Journal, in 1807 .

The first set of experiments was made in 1826, with two pairs of bellows, one pair being exactly double the size of the other, and was intended to show the rates of expansion, and the consumption of fuel. From this experimental machine facts were obtained to show that the former calculations were correct.

The next stage was the construction of an engine of about one H.P., as tested by the friction break, and by pumping water. From data obtained by this engine, it appeared, that the practical economy of the consumption of fuel was about two-thirds of that of a steam engine, doing the same amount of work.

Experiments were subsequently made in London, on a larger scale, the air being raised to a higher temperature; but this was found to affect the working part, and injure the metal. The engine was afterwards taken to Yorkshire, to attempt the removal of certain practical difficulties, and it had been stated, that, from further experiments, these impediments to ultimate success were capable of being removed, and that the invention promised eventually to become a valuable one.

The generator used by Sir George Cayley was a close vessel, in which the fire was placed, and the air was pumped through it. He found it necessary, in order to start the engine, to pump in a little jet of water, which gave a sudden and sufficient power to the engine. In one experiment a steam-jet was substituted for the feed cylinder, when the air was doubled in volume, and came through the fire with great effect. On that occasion the heated air was made to act on an apparatus, on the principle of Barker’s mill, and the general results afforded great encouragement as to the ultimate success of the engine.

Further experiments

Mr. Brunel, V.P., said, he remembered some extensive experiments being conducted many years ago, by the late Sir Isambard Brunel, for the celebrated M. Montgolfier, who came to England about the year 1815, fully impressed with the feasibility of the scheme, which, however, although tried exactly in the manner recommended by Mr. Gordon, applying the expansion directly to the column of water, without the intervention of any machinery, proved a total failure.

The vessels in which the fuel was consumed were of considerable height, and 8 feet, or 10 feet in diameter, so that large volumes of heated air could be employed. The apparatus raised large volumes of water, 20 feet or 30 feet in height, but the result of all the experiments demonstrated, that the amount of mechanical power, derived from the effect of any given amount of caloric on gaseous bodies, was not greater than that produced by the expansion of water into steam, and that practically it was not so generally applicable. The researches of Sir Humphry Davy and Mr. Davies Gilbert confirmed this result.

The experiments on the application of the mechanical power of carbonic acid and other gases, condensed under pressures, which were extended at times to three hundred atmospheres, were continued for nearly fifteen years, at an expenditure of upwards of £15,000; and although at first, and in theory, it appeared a beautiful means of obtaining power, the conclusion arrived at was that commercially it was not so advantageous as that derived from the expansive force of steam; and it must be evident, that the mechanical power obtainable from the expansion of common air, was much less advantageous than that of the more subtle gases.

It appeared then, that although there was little doubt of the mere mechanical difficulties being overcome, there was reason to doubt the application of air engines being more successful at present, than at former periods.

Mr. Gordon observed, that the minimum pressure at which the carbonic acid engine had always worked, was 300 lbs. on the square inch. He well knew the difficulty of keeping any working apparatus tight under such great pressures, from having used, for many years, a powerful apparatus for compressing carbureted hydrogen gas, for illumination, at a pressure of 450 lbs. per square inch. The carbonic acid engine, of Sir Isambard Brunel, was a very different machine from the hot-air engine, which was only subjected to a pressure of 15 lbs to the square inch.

He thought the commercial value of the expansive action of a permanently elastic body might be considered as established; and if that body could be used, there would be a saving of nearly three-fourths of the fuel, because of the difference of the specific heats of water and of air, being nearly in the ratio of 1 to 26/100 ths.

Mr. Brunel, V.P., observed, that he quoted the experiments on condensed carbonic acid gas expressly as bearing on the question, and he could assure Mr. Gordon, that he had succeeded, almost without difficulty, in making joints perfectly tight, under pressures of 1,000 lbs. and 1,500 lbs. per square inch; the experiments he alluded to, for determining the amount of mechanical power, were not made through the intervention of machinery, where there would be friction and other causes of error, but by a simple apparatus, free from these objections, in which the expansion of the gas was made to act upon mercury in another vessel, which was allowed to escape under a certain pressure, and the caloric absorbed by the expanding gas carefully measured, and the results deducted by re-compressing the gas into a liquid, and measuring the heat given out in the operation.

Mr. Robert Stephenson, M.P. V.P., said, it was to be regretted, that although the unfavourable practical results of the experiments on the carbonic acid gas engine had been given, no attempt had been made to account for the discrepancy between the theoretical and practical results.

Mr. Brunel had arrived at the conclusion, that the use of permanently elastic fluids was not productive of economy in fuel, which was the real commercial question, whilst Mr. Gordon, on the other hand, thought he could obtain an effective pressure of 15 lbs. per square inch, by raising the temperature to 480°.

Now, although that was theoretically true, as regarded the fire, it was not practically true, as regarded the piston, and there had not been a single step made towards the mechanical solution of the question. Supposing the thermometer to be a true representation of the quantity of caloric absorbed, there was a wide gap between theory and practice, which no engineer, or philosopher, had hitherto been able to account for. This was, therefore, a most interesting question, and one which he was glad to see brought before the Institution.

It was evident, that there was some discrepancy in the accepted theory, of the expansive force of elastic fluids, under the influence of high temperatures. Like all other engineers, having to deal with locomotive engines, he had to contend with high temperatures, and he had generally found much difficulty in the subject; indeed, it must be expected, when it was remembered, that to obtain a pressure of 15 lbs. per square inch, a temperature of 480° of sensible heat must be employed, which was too high for any material they had to deal with.

The employment of permanent eleastic fluid

Mr. Gordon said, it must be remembered, that the subject under discussion was not the employment of any subtle aeriform body, such as carbonic acid, which was to be compressed into a liquid, and then allowed to expand, working by expansion and contraction like a steam engine; but the paper referred entirely to the employment of a permanently elastic fluid, in the machine introduced by Sir George Cayley, which, as had been stated by Mr. Gurney, worked with a consumption of 1 lbs of fuel per horse power; a statement which could be confirmed, not only from his and Mr. Gurney’s observations, but from the evidence of Mr. Babbage and many other persons, by whom it had been examined, whilst working at different velocities, and always tested by Prony’s brake.

On one occasion the machine had worked up to 20½ H.P.; but when the throttle valve was nine-tenths shut, and the piston was travelling at a velocity of 252 feet per minute, 6 H.P. was maintained. The fuel consumed was 30 lbs. of coke, or only 2 lbs per H.P., per hour.

Captain Ericson’s latter engine, which was made at Mr. Braithwaite’s factory, also worked by the transmission of heat, acting on a piston within a cylinder, and was economical in its consumption of fuel.

Mr. Stirling had also obtained a certain amount of success, of which he had transmitted an account to the institution.

Thus, he must contend, that so far as the mere consumption of fuel was concerned, it might be accepted, as an established fact, that hot air could be made to work cheaper than steam. The wear and tear of machinery, by such high sensible temperatures, was very great, and had, as yet, rendered such machines commercially inapplicable, and on that account Mr. Gordon had rejected all imitations of the form of the steam engine.

He had succeeded in a limited, but highly satisfactory manner, in using a permanently elastic fluid, by causing the fuel and the supporter of combustion - the atmospheric air - to meet in a close furnace, similar to Sir George Cayley’s, and allowing them to cape from thence, under and against the water, at great velocity. Thus the dynamic effect of the hot products of combustion, sufficed to impel a boat, weighing nearly two tons, and giving to it in an initial velocity, equal to that which the formula, published by Professor Robison, had led him to expect.

Into a boat, 26 feet long and 4½ feet broad, I fitted a close furnace, or retort, and a common small forge bellows. The accompanying drawing (Plate 9a) exhibits the whole arrangement. The close furnace being opened at top and at bottom, an intense fire was got up; the bonnets at top and at bottom were then luted and fitted tight. The upper, or reservoir portion of the bellows was not used. Each stroke of the lower portion of the bellows passed air through the close fire, for the hot products of combustion to rush out against, the water, as shown at C.

The boat, when tried with this apparatus, weighed in all 4375 lbs.; in other words, that weight of water was displaced by her flotation when the discharge pipe C was immersed 12 inches.

Each stroke of the portable forge-bellows sent cold air into the close furnace. The appropriation of oxygen to support combustion was instantaneous; and the heating of all the aeriform body which passed off by C was also instantaneous. The products of combustion, almost altogether aeriform, but also occasionally mixed with smoke, dust, and ashes, rushed out (at a temperature of 800° or 900°) by the pipe C, which was 3 inches in diameter.A valve being, of course, in the cold-air pipe, between the bellows and the furnace (and as has been said, the upper chamber of the bellows inoperative), I sent a succession of blasts, into the bottom of the furnace, and, consequently, up through the intense fire, to find its way out under water by the pipe C.

The first blast, by one man, always started the boat (weighing nearly two tons) from a state of rest, 3 feet in two seconds; and I believe that no two tons) from a state of rest, 3 feet in two seconds; and I believe that no two men, with oars, or sculls, with all the advantage of their flexor and extensor muscles, could do more. And neither paddle-wheels, nor the Archimedean screw, can start the same weight into such motion in the same time.

I several times repeated these experiments upon what may be called the initial velocity had by the first blast, or jet, or shot. – (Results of Experiments made with the Fumific Impeller, &c. by Alexander Gordon, M. Inst. C.E., Tract, 8vo., London, 1847).

The result of M. Montgolfier’s experiments, which was almost the experimental philosophy of forty years ago, should hardly suffice to prevent modern engineers from preserving now, in attempts to obtain practically, the advantages promised by theory, and confirmed by well-established experiments.

Mr. Gordon, therefore, contended, that the experiments tried so long since, by Sir Isambard Brunel, did not bear upon the present question, because, in them, carbonic acid gas and other gases had been compressed into a liquid state, and were then used somewhat as water was employed, in the shape of steam, and not at all in the manner which Mr. Ericson, Mr. Stein, Mr. Stirling, and Sir George Cayley had used heated air – these latter having entirely avoided the high pressures which produced liquefaction.

The expansion of air by heat, and its regular uniform expansion, at the same rate, by each degree of temperature, was fixed and known. Dr. Arnott, in his Elements of Physics, stated, that any given quantity of heat, when used to dilate air, produced about four times the quantity of expansive power, that it did when used to expand steam, and Gay Lussac, Levolsier, Laplace, Rumford, Crawford, Dalton, Ure, Thomson, and Turner, all confirmed that view.

Dalton determined that 100 parts of air, being heated from 55° to 212°, expanded to 132-5/10 parts: this gives us an expansion of 1/483 parts for 1o Fahr. Gay Lussac determined the expansion to be 1/486; and although, in Sir David Brewster’s edition of Ribison’s Philosophy, 24/10000, or about 1/417 is stated, we find Dr. Ure, in his “Dictionary of Arts”, (article, “Expansion’), states that all gases expand 1/480 for each degree of Fahrenheit.

The rate of expansion was 1/450 for each degree of Fahrenheit, or one atmosphere of plus pressure was gained by 480° of heat, or two atmospheres by 960° of heat. Mr. Gordon, therefore, repudiated the suggestion of Mr. Stephenson, “that there was some discrepancy, under the influence of high temperatures.” It was evident, that Mr. Gordon’s statement had not been correctly understood, for it had been admitted, that the deductions were “theoretically true as regarded the fire, but not practically true as regarded the piston.”

Now, the Paper before the meeting showed, that the statements were practically true, as regarded the piston also; but Mr. Gordon trusted, the Institution would observe, that his anticipations of success rested almost entirely upon the avoiding the use of any piston. Thus only, he believed would be mechanical world arrive at the practical introduction, for commercial use, of what Mr. Stephenson had, with justice, urged upon the attention of the Institution, as being well worthy of the consideration of the Members.