Lemoine's hot air machine

A fascinating open cycle machine that can work at high pressure.

History

It is known that hot air engines heat up compressed air to have the engine working. Not so in Lemoine's machine.

It differs completely from the hot air engines described so far in that the heat is used to produce cold compressed air for doing work.

Engine Arrangement

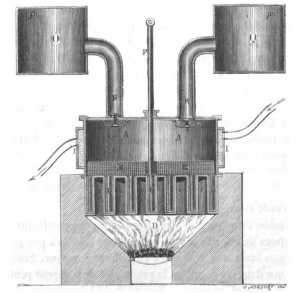

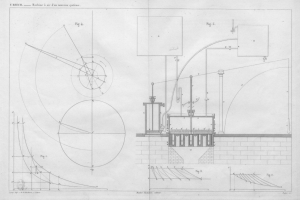

A cast iron cylinder A rests on a furnace D. It is called the fire cylinder. Its upper end is closed by a cover and its lower end has an air tight bottom fitted with small hanging cylinders G. The outer faces of the cylinders G constitute the heating surface of the device.

The fire cylinder has a piston rod F which carries a piston E which is composed of thin layers of metalic meshes similar to those of Ericson. This cylindrical package slides with gently along the internal walls of the fire cylinder, but without touching them. Hanging cylinders G are attached to the piston E, they are closed and engage in the small hollow cylinders G which form, as mentionned, the bottom of the fire cylinder.

A water jacket I in which water circulates, surrounds the fire cylinder and maintains its upper walls at a low temperature. On the contrary, the bottom of the fire cylinder is exposed to the heater by mean of a fairly large heating surface.

The upper cover of fire cylinder has two valves R, S. The valve R is opening from the outside to the inside of the fire cylinder and is communicating with an air reservoir Q at the lower pressure p. The valve S is opening from the inside to the outside of the fire cylinder and is communicating with a reservoir O containing air a higher pressure P.

Operation

The piston E is at the bottom of its stroke and the fire cylinder filled with cold air at a pressure p. The metallic meshes at the top of the piston E are cold, but those at the bottom are hot because they are in contact with the heater.

When the piston E is raised, all the air from the fire cylinder will pass through the successive layers of metallic meshes of the piston E, like through a sponge. On its way from the top layers to the one at the bottom, the air will heat up at the expense of the metallic meshes, that in turn will cool down. By arriving below the piston, the air will come in touch with the hot heater G that will - together with the the radiation - complete its heating.

Since the fire cylinder is closed on all sides, the heating of the air will take place with an increase of its pressure. This pressure, that was p at the start of the upward motion of the piston, will constantly increase as the piston rises, and will reach its maximum when the piston is at the top of its stroke.

When the piston E does its downward stroke, the same air will pass again through the layers of metallic meshes but in the opposite direction. The cooled meshes will pick up its heat and at the end of the downward stroke there will be the same mass of air in the fire cylinder at the same starting pressure p.

In practice the pressure after the double stroke will depend on two factors: the amount of heat supplied by the furnace during the double stroke, and the effectiveness of the water cooling.

What's the purpose to take heat from the furnace and to throw it into the water? Let's see what Lemoine does with it.

The piston E being at the bottom of the fire cylinder starts again its upward motion and the pressure in the fire cylinder increases. When this pressures raises above the pressure P in the reservoir O, the valse S opens and part of the air contained in the cylinder A passes into the reservoir O. The air does so until its pressure within the fire cylinder and the pressure P of the reservoir are equalized.

When the piston E reaches its top level, it starts its downward stroke. The air passes through it depisiting its heat on the metallic meshes. The air cools down and the pressure in the fire cylinder decreases. As a result, the valve S closes as the pressure P in the reservoir is now higher than the pressure in the fire cylinder, and so prevents the air of the reservoir O to return to the fire cylinder. As the air of the fire cylinder is cooling down, there is a time when its pressure drops below the pressure p of the second reservoir (reservoir Q). A vacuum tends to occur that opens the second valve (R) of the reservoir Q and cold air enters the fire cylinder until it is full of air at pressure p.

Then things start again with the newt upward stroke.

The final result of a double stroke is therefore to pass a certain volume of cold air from the reservoir Q into the reservoir O, that is to say from the pressure p to the upper pressure P.

Once the compressed air is introduced into tank O, it can be used by a double-acting cylinder, like steam in ordinary steam engines.

The pressure p of the lower reservoir can be equal to atmospheric pressure, and in this case, the reservoir Q is unnecessary, the valve R draws directly from the atmosphere.

If the pressure p is higher than atmospheric pressure, the closed tank Q becomes essential. But it is enough to compress its air once and for all as it is easy to add a small pump that will - during the running of the machine - supply to this reservoir the needed quantity.

Therefore there will be high pressure machines or low pressure machines.

Distinctive features

1 - High pressure is obtained without any compression

The machine transforms cold air at lower pressure to cold air at higher pressure, without any air compression and with little effort. To raise the piston requires negligeable energy and to lower it requires no enrgy, as the gravity will do it. Therefore in this engine, compression is achieved only with heat and the help of cooling.

This is an important advantage as compression requires at least air-tight cylinders and joints, additional linkeage, a flywheel. Lemoine gets rid of all this.

2 - Most heat issues disappear

The working cylinder is never hot as it is away from the fire cylinder. This takes away many trouble regarding joints, and issue with metal heating.

The piston within the fire cylinder does not touch the internal walls and therefore has no joint issue.

3 - Working at high pressure

One of the drawback of open cycle engines is that they cannot work at high pressure. The Lemoine machine is an exception. This engine is an open cycle engine and can work at high pressure.

But as such it does not bring any benefits, as the main benefit of open cycle engines is to avoid the cooling by water or other means. The Lemoine engine needs a cooling feature and it is one of the few drawbacks of the machine.

4 - Water cooling

The whole idea of the Lemoine machine is to realize the air compression with heat and there it relies heavily on the cooling. This is a contradiction for an engine that can work with open cycle, and is an additional source of hassle.

5 - Dimension

Havin no compression, the Lemoine machine will be of bigger dimension as other hot air engines for the same power.

One way to avoid this is to work at high pressure.

Sources

| Sources | Author | Date | Title |

|---|---|---|---|

| Machine à air d'un nouveau système | F. Reech | 1854 | Comparaison raisonnée des systèmes Ericsson et Lemoine |

| Nouvelle mécanique industrielle | Léon Pochet | 1874 | Machine à air chaud de Louis Lemoine |