Ericsson's Caloric Engine of 1833

Source: Mechanic's Magazine and Register of Inventions and Improvements, Vol III, p. 65

Date: February 1834

Title: Ericsson's Caloric Engine

When we reflect that heat is the great agent in numberless important processes of chemistry and domestic economy, and is the actuating principle of the mighty steam engine which now performs half the work of society, how truly may heat be considered as the life or soul of the universe. — Dr. Arnott.

In our number for December we promised a description of Mr. Ericsson's Caloric Engine as soon as it could be procured. We have much satisfaction in being thus early able to redeem that pledge. The following is from the London Mechanics Magazine.

The Ericsson Caloric Engine

The susceptibility for heat, possessed by gaseous and fluid bodies, is known to be nearly unlimited. Neither density nor pressure seems to exercise the smallest counteracting influence. The densest medium will take up a given quantity of heat with as much facility as the rarest; and when two mediums of unequal temperatures are brought in contact, they become equalized immediately, no matter how different their densities may be.

We have now to direct the attention of our readers to a mode of applying these physical truths to the production of mechanical power, which seems to us to be not only decidedly novel, but to be fraught with results of the greatest public importance.

We allude to the patent recently taken out by Mr. Ericsson, for what he calls his “Caloric Engine.” The grand feature by which this engine is distinguished from the steam engine, and all other power machines, is this, that the same given quantity of heat which sets it in motion is used over and over again to keep up that motion, and that no additional supply is wanted beyond what is requisite to compensate for a small loss incurred by escape and radiation.

We have seen, as well as hundreds of others, during the past week, an engine constructed on this plan actually at work, and can bear our personal testimony to its working as powerfully and equably as any steam engine could do.

The engine which we saw at work is, in all external respects, saving only the small space which it occupies, exactly similar to a high pressure steam engine. It is calculated to be of five horse power. There are two cylinders: one called the cold cylinder, 10 ¼ inches in diameter, and the other the working cylinder, 14 inches in diameter, both with an 18 inch stroke.

The engine was worked under a pressure of 35 lbs. to the square inch, and its power checked by a break, loaded with 4,000 lbs., acting on the circumference of a wheel of 2 feet diameter.

The circulating medium employed in this engine is simply atmospheric air; but of course that or any other fluid medium may be employed with equal facility for the purpose of using the heat over and over again—some perhaps with much greater facility.

The Caloric Engine description

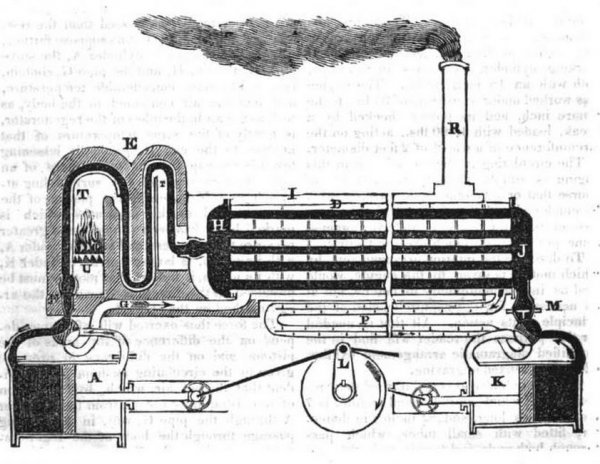

To describe the interior arrangements, by which motion is given to the engine, would lead us into a multiplicity of details, not at all necessary for the comprehension of the principle of its action. All that is needful for this purpose the reader will find in the simplified diagramatic arrangement exhibited in the prefixed engraving.

DD is a cylindrical vessel termed the “regenerator,” which, in the actual engine, is 7 feet 6 inches long, and 8 ¼ inches in diameter, fitted with small tubes, which pass through both ends, and terminate in the caps H and J. It also contains a number of division plates, through which these tubes pass, and which plates have segments cut out alternately from their tops and bottoms.

The tubes themselves likewise contain a number of small divisions, tapering off towards the centre, each placed in an opposite direction to the other. TT is one of a series of bent tubes, inclosed in a stove, E and acted upon by the fire, U, the combustion being supported by the draft produced by a chimney, R. The pipes in the stove are all connected with two larger pipes, the one of which communicates with the cap, H, and the other, as shown by the diagram, communicates with a four way cock, attached to the passage pieces of a cylinder, A, which is the working cylinder of the engine.

P represents one or more pipes, exposed to some cooling medium and is termed the “cooler;” it contains also a number of division plates, similar to those in the tubes of the regenerator, as also with the four-way cock attached to the cylinder K.

The Caloric Engine working

The whole of the apparatus, namely, the body of the regenerator, its tubes the caps H and J, the pipes in the stove, the cooler P, pipe G, and the two cylinders, with their passage-pieces, we will now suppose to be all charged with common air, or any other aeriform substance.

We will suppose also that the portion of that air which is marked black in the diagram is kept under greater pressure or more compressed than the rest, which is left blank. Let us suppose farther, that the air which the cylinder A, the stove pipes T, the cap H, and the pipe G, contain, is raised to some considerable temperature, and that the air contained in the body, as well as the air in the tubes of the regenerator, is nearly of the same temperature of that nearest to the cap H, gradually lessening towards the cap J, so as to be there of an equal temperature with the surrounding atmosphere.

Now, since that portion of the air contained in the apparatus which is marked black has been changed to a greater pressure than the rest, and as the cylinder A, with its piston is larger than the cylinder K, with its piston, it follows that motion must be produced in the direction shown by the arrow marked on the crank L.

The force thus exerted will, of course, depend on the difference of the areas of the pistons, and on the difference in pressure 3 the circulating medium. It is evident that the hot air, which, by the motion of the piston, must escape from the cylinder A through the pipe G, will, in its winding passage through the body of the regenerator towards the cooler P, give out its heat to the cold air forced from the cylinder K, the particles of the latter being also in a constant state of change in passing through the tubes towards the stove pipes.

The pistons having performed the full stroke, the two four-way cocks are then reversed, when a retrograde action takes place; the motion of the opposite currents in the regenerator still continuing the same as before. A constant motion will thus be produced, and a constant transfer of heat kept up.

The object of the cooler P is to abstract the heat, which, on account of the different capacities for heat of the two currents, is not taken up in the regenerator, and the object of the stove is to supply the heat thus carried away as well as to compensate for losses by radiation, and to raise the temperature at the commencement.

It need hardly be stated that the lesser volume of air coming from the cold cylinder fills the larger space in the hot cylinder, because it gets heated in passing through the regenerator and through the stove; while on the other hand, the larger escaping volume from the hot cylinder finds room in the lesser space of the cold cylinder, because it parts with its heat before getting there.

By charging the apparatus, the circulating medium may, of course be kept under any desirable pressure, and thus the power of the engine varied at pleasure. High pressure will naturally produce the greatest proportionate effect, the loss by radiation being the same under whatever pressure.

We were anxious to satisfy ourselves as to the equality of the action of the engine, and with this view timed it repeatedly: the number of strokes was regularly 56 per minute.

The total consumption of fuel, when the engine is working at this rate, is stated to be no more than two pounds per horse power in the hour; and the entire loss of heat incurred by the transferring process (that is, the whole heat carried away by the cooler,) is estimated not to exceed the product of 3 lbs. of fuel per hour. That the fuel required is not even less than two pounds is solely owing to the great radiating surfaces unavoidable in an engine on a small scale, and to these radiating surfaces not having in the trial engine been covered by any non conducting substances.

Principles of the Caloric Engine

Mr. Ericsson has published a pamphlet explanatory of the principle and construction of his caloric engine. We extract from it the following additional information:

By keeping the pipes in the regenerator so charged with air as to support a column of mercury 56 inches high, the greatest effect is produced in the trial engine. By the manner in which the side-valves are worked, the pressure in the body of the regenerator always adjusts itself, so as to support a column of mercury 18 inches high: so that an effective pressure equal to 38 inches of mercury, is kept up. A break, well oiled and loaded, with 5,000 lbs. weight acting on the circumference of a wheel of two feet diameter, fixed on the fly wheel shaft, will at the above pressure keep the speed of the engine at 55 revolutions per minute.

At this speed, 176 cubic feet of heated air, of a mean pressure of 17 lbs. to the square inch, are admitted into the working cylinder per minute, thereby exerting a force equal to 431,970 lbs. moved through the space of one foot: thus 431.970/ 33.000 = 13 horses power are communicated to the main crank of the engine. The estimating this power is, however, of no other use than to give an idea of the amount of friction to which the crank-engine is subjected. In the same space of time, or a minute, 94 6 cubic feet of cold air, of a mean resistance of 14 lbs. to the square inch, are forced or put into circulation by the cold cylinder, and equal to a resistance of 190,575 lbs. moved through the space of one foot. This amount divided by 33,000 will give 5-7 horses’ power required to work the cold cylinder, hence the two cranks give and receive the power of upwards of 18 horses.

By communicating the power of the hot cylinder to the cold cylinder in a direct manner, the available power, setting frictions aside, would be 431,970 - 190,575 = 241,395 lbs. moved through the space of one foot. This is equal to 241.395/ 33.000 = 7.3 horses’ power - deducting 2.3 horses for frictions would leave 5 horses. On these grounds the trial engine has been estimated at 5 horses’ power.

The transferring process has succeeded to such an extent, that out of the 10 lbs. of fuel which the engine consumes per hour, the product of heat from 3 lbs. of fuel only are wasted or carried away by the cooler. This important fact has been ascertained by immersing the cooler in a cistern containing precisely 1081 lbs. of water and by observing the elevation of temperature after an hour's work of the engine; and the increase of temperature in that time is not quite 20 degrees — one pound's weight of fuel being capable of raising the temperature of 9,000 lbs. of water, it follows that the 1081 lbs contained in the cistern would be raised 8.3 degrees by the combustion of 1 lb. of fuel, and hence that the actual increase of 20 degrees of temperature is effected by the combustion of less than 3 lbs. of fuel.

The great discrepancy between the quantity of fuel thus wasted, and that actually consumed by the engine must be accounted for by the fact, that a considerable extent of radiating surfaces are exposed to the cooling influence of the atmosphere without being surrounded by any imperfect conductors.”