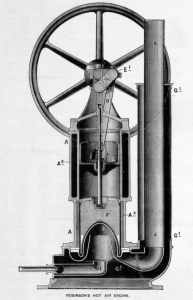

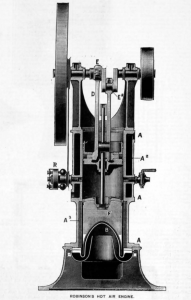

Robinson hot air engine - 1881

The Robinson hot air engine of England uses the displacer as a regenerator.

|

||

| Inventor | Arnold E. Robinson and Horace Robinson, Manchester, County of Lancaster, England. | |

| Country | England | |

| Year | 1881 | |

| Patent | Yes, No.5,056 | |

| Operation | Closed cycle | |

| Combustion | External | |

| Engine type | One cylinders | |

| Working piston | Single acting | |

| Output | 0.25 HP to 1 hp | |

| Fuel consumption | Coal, gaz, oil, others |

History

The Robinson machine is a small closed hot air machine, which was constructed by Frank Pearn and Co. in Manchester, according to the English patents of Robinson and Robinson. This machine is characterized by an extremely simple design and compact structure with simple movement mechanisms, and has the special peculiarity that the displacer ahs also the function of a regenerator.

Engines of this type were shown at work in the Machinery and Metal Trades' Exhibition; they ran with great ease and quickness.

This Robinson engine looks like an improvement of the Lemoine hot air engine, who used a piston being also a regenerator. The Robinson engine adds a working piston and therefore uses optimally the advantage of the air compression.

Engine Arrangement

The engine is simple and compact, and gives a steady driving motion. Compactness has been secured by several well considered devices, among which the arrangement by which the heating and cooling surfaces are kept close together, without transmission of heat taking place between them so permitting of a considerable difference in their temperatures.

G2 is a chamber or fire-box lined with a nonconductor of heat, G is the chimney, and G1 a casing which forms a space leading to G2, round the outside of the chimney. The dome-shaped bottom B of the cylinder is heated by means of a gas burner H whith can be withdrawn for lighting, and which is supplied with air previously heated by being passed down the space between G and G1, thus utilizing a considerable portion of the waste heat and causing a more perfect combustion of the gas.

The upper part of the cylinder A is open at one end and is surrounded at its upper end by a cast iron jacket A2 which is always kept cool by water which flows in it. The other end of the cylinder, which is heated, is surrounded by a liner A3, which is a fairly thick layer of a poor heat conductor like fire-clay. The object of the liner is to more effectively confine the heat within the cylinder so that it shall not be readily transferred to the metal and dissipated, and also to separate the heater B from the cooled part of the cylinder.

The working piston C is connected to the pin E1 of a double throw crank by mean of the connecting rod D. The displacer F is connected to the crank-pin E2.

The most notable part of the machine is the displacement piston F. In order for it to be able to serve also as a regenerator, its upper perforated plate adjoins the cylinder wall and forces the air to make its way through the piston body that is filled with heat-storing material. The piston rod of the displacer is sealed in the working piston by a stuffing box and finds a second guide in the crossing metal piece above the cylinder.

The working piston C and the displacer F move in the same upright cylinder and are directly connected to the double cranked flywheel shaft by means of the connecting rods; the displacer is leading the piston by 90°.

Operation

The action is derived from the alternate heating and cooling of air, and its consequent expansion and contraction.

When the displacer - which is leading the working piston by 90 ° - begins its upward stroke,the working piston is doing the second half of its downward stroke. The air located between the two pistons is therefore driven through the displacer where it absords a certain amount of heat, and then directed to the heater B when the working piston reaches its lowest position. There it is strongly heated up, and as a result of the increase of temperature, the air expands and has a driving effect on the working piston C, which now starts its upward stroke. This is the power stroke.

Both piston move upwards, the working piston is doing its first half of the upward stroke, the displacer is doing the second half.

When the working piston starts the second half of its upwards stroke, the displacer begins its move downward, from the cooled to the heated end. The air contained in the heater passes through there a large part of the heat contained in it. The complete cooling then takes place on the cold walls of the working cylinder, against which the air is directed through the plate fixed above the displacer as it emerges from it. The air looses its heat, in consequence of which it contracts in volume and allows the piston to descend.

The regulation takes place by the regulator which allows part of the tense air to escape if the engine is too fast, or by hand using the cock.

Distinctives features

The Robinson engine is part of the few engines that use the displacer as a regenerator. Such a construction has all the advantages of a engine having a displacer plus a regenerator, though having less components. Robinson added the a perforated plate at the top of the regenerator that guided the air passing through it and avoided the losses along the cylinder walls.

The use of a displacer as a regenerator was therized by Reech on his work on Lemoine's air engine in which he recommanded the use of a working piston as it is done by Robinson (see article sources). But Robinson did it in a closed-cycle engine.

The working piston is guided by a fixed rod to avoid the additional friction imparted by the oblique force of the connecting rod on the cylinder walls.

The heater is built in such a way that is reuses the heat of the exhausted gas to heat the incoming air and therefore permits additional fuel economy.

Manufacturers

The Robinson hot air engine was manufactured by Messrs. Frank Pearn and Co. of Manchester, who were the sole makers.

| Gallery | |

|---|---|

|

|

|

|

Sources of information

| Document | Author | Date | Title |

|---|---|---|---|

| Machine à air d'un nouveau système | F. Reech | 1854 | Comparaison raisonnée des systèmes Ericsson et Lemoine |

| The Engineer | Anonymous | 1883 | The Engineering and Metal Trade Exhibition |

| Polytechnische Journal, Band 249, (S. 409–410) | Anonymous | 1883 | A. und H. Robinson's Heissluftmaschine |