Open Cycle Air Engines

| Open Cycle | Closed cycle | Description | ||

| Direct heating | These air engines have an open furnace that heats the working fluid externally. This means that the working fluid is heated indirectly and not directly. The engine works on an open cycle. At the beginning of each cycle fresh air is taken from the atmosphere and, after being heated and having done work, it is rejected into it. NB: In general open cycle engines can be easily turned into closed cycle engines. Examples of open cycle hot air engines: - The Ericsson caloric engine - The Wilcox air engine. |

|||

| Indirect heating | Open cycle engine | |||

| Atmospheric | ||||

Inventors of open cycle air engines

| Year | Inventor | Country | Engine page |

|---|---|---|---|

| 1830 | Ericsson | Sweden / England | Ericsson wheel engine |

| 1847 | Lemoine | France | Lemoine moteur à air chaud |

| 1851 | Ericsson | Sweden / America | Ericsson caloric engine |

| 1853 | Woodbury | America | Woodbury atmospheric engine |

| 1854 | Shaw | America | Shaw air engine |

| 1860 | Wilcox | America | Wilcox air engine |

Engine characteristics

Those machines in which only the pressure generated by the expansion of the air is used as motive power are called open machines, since here the air once used must always be replaced by fresh air; on the other hand, those machines which also make the contraction of the air by cooling it usable are called closed machines, since only one and the same air quantum is used here.

Open machines are those in which new air is always supplied to the working cylinder by an air pump, which, after it has warmed up and released the work done by the heating, escapes from the machine.

The open machines usually are single-acting and mainly consist of a working and an air pump cylinder which can either be separate, or combined in one piece so that both pistons work in a common cylinder.

The piston of the working cylinder by means of a rod engages the crank directly or by lever transmission. The pump piston is directly coupled to the working piston. The single-acting air pump has suction and pressure valves.

An inlet and an outlet valve are used to control the machine; the former connects the interior of the working cylinder at the right moment with the hot air that had been in a closed room until then, while the outlet valve, after the stroke has been completed and the inlet valve is closed, allows the heated and tensioned air to escape from the machine. It thus cancels the counterpressure at the beginning of the downward stroke, which is done solely thanks to the work accumulated up to that point.

During this phase of the cycle the machine will also to deliver work. As a result these machines require heavy flywheels to achieve a normal degree of uniformity in their movement.

The furnace is either separated from the working cylinder or arranged together with it, but do not interfere with the inside of the cylinder. In such open engine part of the heat is lost through the furnace and lost for the performance of the machine.

Theory

On its way through the machine the atmospheric air - also called the working fluid because it will do work - is cycling through it. This thermodynamic cycle can be represented graphically as follows.

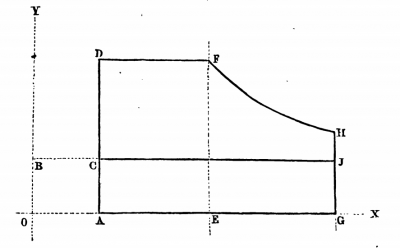

OX is the abscissa axis on which is drawn the air volume, OY is the ordinate axis on which is drawn the air pressure. The quantity of air compressed by the pump has the volume OA and its pressure is AC = OB.

This amount of air is heated while its volume is kept constant. At the moment the pressure has reached a certain level AD, the heating of the air continues, but the working receives hot air thanks to the opening of an inlet valve. As a result the air pressure remains constant AD = EF, but its volume increases from OA to 0E.

The working piston travels a distance and then the inlet valve is closed to stop the air supply ; the air in the cylinder starts to expand from the pressure level EF to the pressure level GH. When the pressure arrives at H, an outlet valve opens and put the inside of the working cylinder in contact with the atmosphere. A portion of the hot pressurized air flows immediately out, and its pressure drops to the atmospheric pressure GJ. The remaining air is finally pushed out. Fresh air is then again sucked in by the air pump while the machine is doing its way back.