Arnott's Hot Air Engine

Source: Elements of Physics or Natural Phylosophie, Vol II, part 1

Date: 1829

Title: Expansion of Airs

Author: Neil Arnott

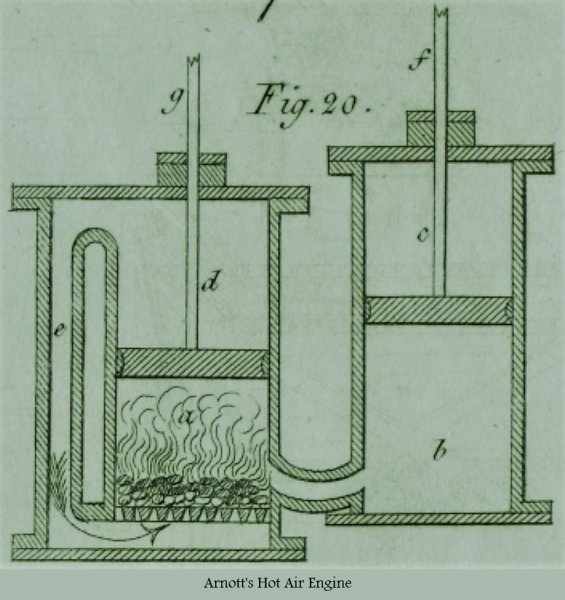

If we suppose a fire a to be placed on a grate near the bottom of a close cylinder, d a, and the cylinder to be full of fresh air recently admitted, and if we then suppose the loose piston g d to be pulled upwards, it is evident that all the air in the cylinder above d will be made to pass by the tube e through the fire, and will receive an increased elasticity tending to the expansion or increase of volume, which the fire is capable of giving it.

If there were only the single close vessel d a, the expansion might be so strong as to burst it; but if another vessel b c of equal size were provided, communicating with the first through the passage b, and containing a close-fitting piston c f like that of a steam-engine, the expansion of the air would act to lift the said piston, and by means of it might work water-pumps, or do any other service which a steam-engine tan perform. At the end of the lifting stroke of the piston f c, it might be made to open an escape-valve for the hot air, placed in any convenient part of the apparatus, and to cause the descent of the blowing piston d to expel this, while a new supply of air would enter by another valve into the cylinder above d. The engine would then be ready to repeat its stroke as before, and the working would be continued as in a steam-engine.

The preceding simple conception of an air-engine occurred to the author’s thoughts while considering the application of a condensed-air furnace to some chemical purposes. It appeared to him that the chief difficulties to be surmounted in applying any such engine to use would be, to prevent the very heated air and dust from injuring the valves and other working parts of the engine, and to obviate the inconvenience of the inequality of power at different parts of the stroke.

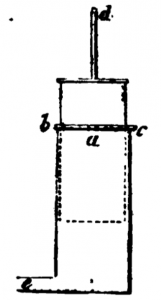

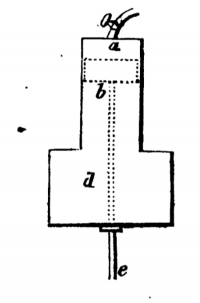

Various expedients occurred to him. The overheating might be prevented by surrounding the cylinder, with water; and both cylinder and piston would suffer less from dust if; instead of the common piston c, represented above, a great hollow plunger a were used (such as is here represented, and is now common in water-pumps for mines), embraced by an air tight neck or collar at b c, which neck would be the only part of the cylinder requiring to be made with nicety.

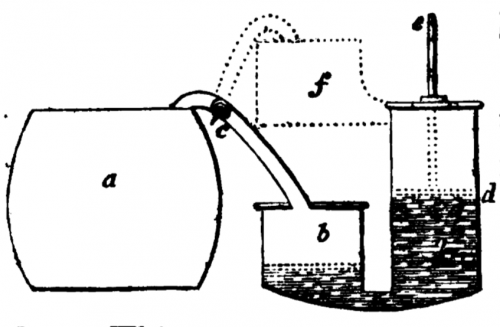

But a more complete security would be obtained by interposing water between the hot air and the piton, as represented in this in sketch, where the working cylinder d has a water-vessel b connected with it, and the heated air is admitted to press upon a float on the water-surface, to lift the working piston d e.

This construction, too, if desired, would allow the fire-chamber a to be made larger than the cylinder, and to be kept constantly filled with highly expansive air, each discharge of which in the space b would be replaced by cold air either from the space above d, driven in through a tube as the piston ascended, or from a distinct blowing cylinder worked by the beam.

And if it were wished to apply the same principle to an engine working with double strokes, that is, forcing the piston alternately up and down, as in the double strokes steam-engine, the object might be attained, by having a second water vessel f, communicating with the part of the working cylinder above the piston d; and the air would pass alternately to the one or the other vessel b or f by the operation of the cock c, as steam passes in a steam-engine: the supply of fresh air to the chamber a would be given by a blowing cylinder worked through a connexion with the engine, as the air-pump of a steam engine is worked.

The sketch of an air-engine, as here given, was included in the specification of a patent for another object engaged in some years ago by a friend of the author’s; but he being almost immediately called to other business, and the author’s professional engagements precluding his attention to the subject, it was not prosecuted.

In the specification, drawn up by an engineer in town, some minor adaptations were described. One experiment has lately been made by a Swedish engineer with the simple form of dry apparatus described above, for the purpose of ascertaining its power, and the effect was found to be several fold greater than of steam from the same quantity of fuel; but the apparatus was rude, and only calculated to prove in a short trial, the existence of the power, but not the fitness of the machine to endure long uninjured, and to be rendered easily obedient to control: a complete experiment therefore remains still to be made.

Could an obedient and durable engine be contrived, at all approaching in simplicity to the plan given above, its advantages over the steam-engine would be very considerable.

-

First, its original cost would be much less, by reason of its small comparative size, simplicity, and the little nicety of workmanship required.

-

Secondly, it would occupy much less room, and would be very light; hence its peculiar, fitness for purposes of propelling ships and wheel carriages.

-

Thirdly, the quantity of fuel required being so much less, would not load the ship or carriage, leaving lit tie room, as happens in steam-boats, for any thing else.

-

Fourthly, the expense of fuel and repairing would be little.

- Fifthly, the engine could be set to work in a few minutes, where a steam-engine might require hours. Sixthly, little or no water would be required for it.

Gas vacuum Engine

Another modification of air-engine, called a gas vacuum engine, has lately been proposed, and many expensive trials have been made of it; but it is in its nature a most wasteful machine, evidently throwing away at least nine-tenths of the power which its principle generates.

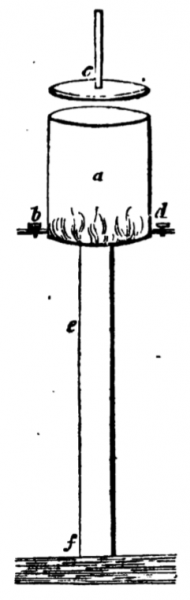

It was of this nature in an experiment which the author witnessed. A little of the common coal-gas was admitted by the cock b at the bottom of the cylinder a, and was there inflamed, the lid c being at the time raised. The combustion rarified the lower stratum of air, so that the air above was expelled, and about one-fifth of the original contents of the cylinder was made to occupy the whole.

The lid was shut down as nearly as could be judged at the moment of greatest expansion, so that when the small portion of air and vapour remaining was again cooled, the interior of the cylinder approached nearly to the state of vacuum.

It, in fact, retained only a fifth of the air. A communication being then opened by the tube e from the vacuous cylinder to a water reservoir ten feet below, the water was driven up by the atmospheric pressure, and filled more than half of the cylinder. The water so raised was then made to turn a common water-wheel, and so to do work. A larger quantity of water, however, could be raised to the same height at less expense by a steam- engine.

The proposer also hoped that be would be able to make the atmosphere pressing into his imperfect vacuum, act directly upon a piston as steam does, and with power cheaper than that of steam; but in this anticipation too he was completely in error. To produce his imperfect vacuum cost him very nearly at the same rate as it costs to produce the perfect vacuum in a steam-engine, and his vacuum for equal bulks was worth, as a working power, only about one-fourth as much as the steam vacuum.

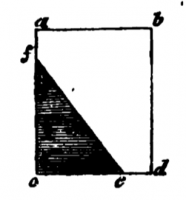

This may be understood by considering that in a perfect vacuum a piston rises all the way with the same force, which if common steam be used, is 15 lbs. per inch (the piston may be supposed rise from c d to a b), but if the vacuum were only three-fourths towards being perfect, the pressure on the piston would be only three-fourths of 15 lbs. at the commencement of the stroke, would then rapidly diminish, and would have ceased altogether when the piston had made three quarters of its journey, or to f. The force in the first case would be represented by the whole line e d and the square space c d b a, and in the second by the shortening lines and the triangular space e e f.

On considering the foregoing diagrams we may perceive that in the vacuum-engine, by far the greater part of the force produced by the combustion of the gas is absolutely wasted, or put to no use, viz the whole expansive force, during the sudden combustion or explosion.

It is evident that if a tenth part of the aeriform contents of a cylinder acquire elasticity enough - and a fourteenth part in a nice experiment does so - to be able afterwards to occupy the whole cylinder, it must begin its expansion with the force of a tenfold atmospheric condensation, that is, a pressure of 150 lbs. on the square inch of a piston withstanding it, which pressure will then gradually diminish as the piston rises, but will amount to an average of five times the atmospheric pressure, or 75 lbs. per inch all the way; being therefore quadruple or more, that of steam against a perfect vacuum, and therefore again, by our former calculation, at least twelve times greater than the force obtained from the imperfect vacuum of the engine under consideration.

It is a question which the author thinks will one day be answered in the affirmative, whether nearly the whole force of exploding gas may not be converted into a calmly working power, producing from a given expenditure, ten times or more the effect obtained in the vacuum engine described above, and therefore more than from a steam-engine incurring the same expense. There are probably various ways in which the object may be attained. The following sketch is offered merely to give the reader an idea of a machine for such a purpose.

Suppose b to be a very heavy, close-fitting sliding in the cylinder around it, and suppose the space d open to the cylinder, to be filled with atmospheric air of double or greater density; then if a mixture of explosive gases admitted by a cock to the chamber (formed between the piston and end of the cylinder) be inflamed, the heavy piston will be shot forward, like a cannon ball, against the condensed air in d; and owing to the momentum acquired in the first in stance, it will advance much beyond the point where the exploded gas and air in d would balance each other at rest: the quantity of gases admitted would be just such as to carry it to the end of the cylinder.

The piston rod e would then by a catch or ratchet, be connected with the work to be done, and after the condensation of the exploded gases in the cylinder, would be pressed back again, with the double or greater than atmospheric force in d, as if urged by high pressure steam. The first figure at page 74 represents a form of cylinder which might also answer for this purpose, the heavy plunger being thrown up, to work by its weight in descending.

It is to be remarked that the first modification of air engine described above, is partly an explosive engine such as contemplated above, for the gas separated from the coal during the moment of slackened combustion while the lately used air is passing out, becomes an explosive accumulation for the fresh air about to enter.

The trial alluded to above proved this to be the fact.