James Woodbury, Joshua Merrill, George Patten and Edward Woodbury

A quest for perfection

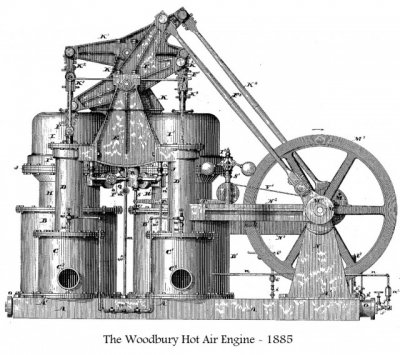

The Woodbury hot air engines were built by the firm of James Woodbury, Joshua Merrill, George Patten and Edward Woodbury, Boston, Massachusetts, USA.

During four decades the four inventors stuck together for developing an perfecting a hot air engine. Their endeavor was done in two steps : the early hot air engine of 1853 and the second hot air engine of 1880.

Their first hot air engine was built in the early 1850s' and patented in 1853. Has it been a failure ? Probably. First, because the reading of the two patents shows some serious mistakes that can be explained only because thermodynamic was still a very young science at that time. Second, because very little is known about this engine and often this is a confirmation of a lack of success.

Nonetheless, for the Woodbury firm, 1853 has at least been the start of a long quest for perfection. Although during a quarter of a century, nothing visible happened on their side, it looks like the Woodbury inventors took all necessary time to understand the hot air engine. Obviously they aimed at building engines of higher power. With this goal in mind, the inventors had to let aside the atmospheric engine that was not suited for high power. They decided to develop and build a new engine, a closed-cycle hot air engine.

From 1879 on, there was a flood of Woodbury & Co. patents filed during almost a decade. The US Patent Office has records of over 15 patents filed between 1853 and 1889. Except the two patents of 1853, all of them were filed after 1879.

A major innovation : the reverser

A thorough reading of them shows that the Woodbury inventors did understand two major facts about hot air engines.

First, they recognized that they are only two ways to achieve high power hot air engines. One way is to have internal combustion, the other is to work with high pressure in a closed-cycle engine.

The latter solution was their choice and the obvious reason was that the Woodbury firm wanted to take advantage of the regenerator and its improvement potential, in order to improve the engine efficiency, means have more energy output for the same fuel cost.

Internal combustion is not compatible with a regenerator.

Second they understood the crucial role of the heater for the success of an air engine. They specifically patented a "heater for hot air engine" in 1879, that was regularly improved.

Their idea was to have a close working between three essential parts of the engine : the heater, the regenerator and the cooler. Out of it came their major innovation : the reverser.

The reverser combines all three technologies (heater, regenerator and cooler) in one sole body, fully separated from the working cylinder. Indeed this was a big step in the unknown as the cooler has always been stuck to the working cylinder.

The birth of a perfect hot air engine

Twenty-five years of searching, triying, developing and hard laboring resulted in 1880 in the birth of their second engine. It was still an experimental engine, but was most promising. Various engines were then built by the Woodbury firm, with regular improved arrangements. Some did satisfactory work, some failed, some did run for periods of several years.

Finally, by the end of the 1880's Woodbury & Co. were able to bring to the market an utmost, if not perfect, hot air engine of their construction, crowned by their 1889 patent. The engines were claimed to be superior in durability to any hot air engine constructed before and very economical.

The engines were claimed to be superior in durability to any hot air engine constructed before and very economical.

Their fuel consumption would be extremely low. In a test made in South Boston, the quantity of coke consumed was 0.7 Kg (1.5 pound) per HP per hour. This figure has to be compared with the usual fuel consumption of the external combustion hot air engines of the 1850-1920's that averages 1.8 to 2.2 Kg (4 to 5 pounds) of coke or equivalent per HP per hour.

Regarding its operation, it is said that the Woodbury engine did surprise by its general excellence, its smoothness of movements.

(to be continued)