Paper - Newcomen Society

Source: The Piston Engine Revolution

Title: Sir George Cayley’s Hot Air Engine, 1837

Author: Bryan Lawton, Newcomen Society

Sir George Cayley (1773-1857) was born in Scarborough, Yorkshire and was the son of wealthy parents living at Brompton Hall and his education included mathematics, navigation and mechanics.

In 1792 he inherited the baronetcy and was faced with the task of reviving the family’s estate. He developed and early interest in aeronautics, copying, in 1796, a toy helicopter invented by Lauoy and Bienvenu in 1784. This convinced him that a machine could be made to “rise in the air by mechanical means”.

In 1799 he inscribed his ideas on a silver disc, now in the Science Museum, London. One side showed the forces on a wing resolved into lift and drag and, on the other side, was his idea for a fixed wing aeroplane. He tested possible aircraft wings using a rotating arm and measured the lift and drag of cambered aerofoil sections.

In 1809 he successfully flew an unmanned, full-sized glider. He wished to attain manned flight but he realised that to do this he would need a suitable engine for his glider.

Steam engines were too heavy, but he experimented with a gunpowder engine and, in 1807, with a hot-air engine. He did little in the next twenty years but he eventually turned his mind towards finding a suitable engine.

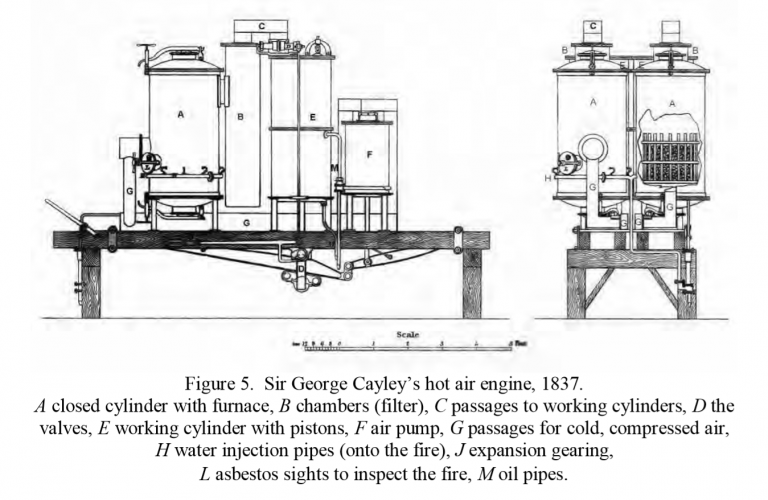

In 1837, Cayley applied the products of combustion from a closed furnace so that they would act directly on a piston in a closed cylinder. A pair of his engines is shown in Figure 5, which is based on a description of the engine in a paper by Poingdestre.

An air pump, F, delivered compressed air through a pipe G to a closed vessel A containing a coal fire. The pressurised air supported the combustion of coal in the closed vessel and the exhaust products, at 600°F (315°C) were passed through a chamber, B, filled with wire mesh to separate any ashes or cinders, and from there into the working cylinder E that was fitted with a piston and valves very similar to a single acting steam engine. The hot, high-pressure combustion products were expanded in the cylinder thus producing power.

The engine was started by throwing (injecting) a few drops of water upon the closed fire, which evaporated and gave an impulse to the engine, causing the immediate action of the air pump, which then continued to work regularly and the engine continued to work. The fire was replenished by stopping the blast from the furnace and opening the upper bonnet.

The cycle was, in fact, the same cycle of operations as the modern gas turbine, namely, compression, heating at constant pressure followed by expansion. The main difference was that Cayley’s engine used a reciprocating compressor and a reciprocating expander, whereas modern gas turbines use rotary compressors and expanders (turbines).

Had he but realised it, Sir George Cayley had, in this engine, the principle of the very engine he was seeking for his major interest, namely, manned flight in a heavier than air machine.

Cayley’s hot air engine seems to have worked for a short time but it could not be made sufficiently reliable for commercial purposes. Poingdestre says that between them the two cylinders developed 8 hp when the piston travelled at 220 ft/min and he states that the high temperature was found to destroy the valves, piston, and cylinder and likewise to carbonise the lubricating oil. Hence there was great difficulty in keeping the working parts in order.

It is likely that the dirty nature of the gas leaving the furnace was also a major problem. When gas engines were later developed to operate on the waste gas from blast furnaces it was found that cleaning the gas before it was passed to the engine was essential if the engine was to be reliable and easily maintained.

Sir George was certainly aware of this problem but it seems that his filter in chamber B was not sufficiently good. Certainly, it did not have sufficient reliability to power an aeroplane. In the discussion to Poingdestre’s paper, Goldsworthy Gurney recalled that Cayley had carried out experiments in 1826, using two pairs of bellows. He then constructed an engine of about 1 hp, tested on a friction brake and by pumping water, and it appeared that the fuel consumption was about two-thirds that of a steam engine of the same power.

In the same discussion Gordon gave the fuel consumption as 6 lb of coal per hp hour, which corresponds to a rather modest thermal efficiency of about 3.1%. When the throttle valve was nine-tenths shut, and the piston travelled at 252 ft/min, 6 hp was obtained at a consumption of 5 lb/hp hour.

Experiments were then made in London, on a larger scale, and raising the air to a higher temperature, but this was found to affect the working parts and injure the metal. The engine was subsequently taken to Sir George’s home in Yorkshire to remove these practical difficulties. It was thought that the invention promised eventually to become a valuable one. In one experiment a steam jet was substituted for the feed cylinder, when the air doubled in volume and came through the fire with great effect.

On that occasion the heated air was made to act upon an apparatus on the principle of Barker’s mill (that is, using a jet to produce thrust), and the general results afforded great encouragement as to the ultimate success of the engine.