Sylvester H. Roper

Source: an article from Scientific American, Vol. XX, N°17.

Date: April 24, 1869

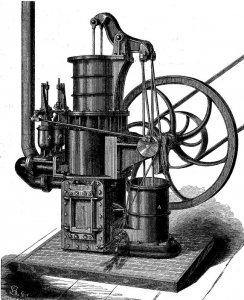

Title: The Roper Improved Caloric Engine

The Roper Improved Caloric Engine

The attempt to substitute air for steam, as a motive power, is not so recent as is generally supposed, patents having been granted in this country as far back as 1824, for atmospheric engines.

It appears to have been first used, in a really efficient form, by Rev. Dr. Stirling, of Scotland. He patented an air engine in 1816, and made one which was used for pumping, in 1818, that worked for a short time.

In 1807 Sir George Cayley constructed an air engine in which air was heated inside of the furnaace.

In 1827 Parkinson & Crosley, of City Road, London, England, constructed an air engine, externally fired.

In 1833 Lieutenant John Ericsson, then residing in London, reduced to practice his long-cherished project of a caloric engine, and submitted the result to the scientific world. The invention excited very general attention, and lectures in explanation and illustration of its principles were delivered by Dr. Lardner, Prof. Faraday, Dr. Andrew Ure, and others.

In 1837 Sir George Cayley constructed an new air engine.

In 1851 Ericsson patented his invention in this country, and in 1852 he built the ship Ericsson, of 2,000 tons, driven by his machine, the working cylinder of which was 14 feet diameter, with six feet stroke.

Since then the engine has been considerably improved by himself and others, and it is now recognized as a cheap, safe, and efficient generator of power, within certain limits, and is extensively used in this country.

The most perfect form of the engine, with which we are acquainted, is that shown in the accompanying engraving, known as the Roper Caloric Engine, which was first illustrated in No. 7, Vol. VIII., Scientific American, since which time it has been greatly improved, as the accompanying engraving and description indicates.

This engine should not be confounded with other air engines that depend upon heated air alone. Mr. Roper claims to have accomplished, in his engine, what others have attempted and failed, and what experienced engineers claim necessary to a successful caloric engine, viz.: forcing the air directly into the fire, and thereby combining the power of expansion with the power and products of combustion.

This result is accomplished, in this engine, by the use of an air pump, close, air-tight doors to the furnace, and poppet valves, arranged as follows:

The air, to supply oxygen for the combustion, is pumped in by pump, A, the carbon is burned rapidly and completely, under press ure, and the resulting carbonic acid gas and uncombined hydrogen gas from the air pass from the generator, or fire box, to the piston by use of poppet valves, B, which act the same as steam marine engine valves.

With this arrangement a quiet, steady pressure is continued in the fire-chamber, or air boiler, and the great difficulty experienced in others, of a blast carrying ashes and too great a heat into the cylinder and burning out packings, is fully obviated.

The inside of the fire-box, C, is lined with heavy fire-brick throughout, and a wall of non-conducting material, three inches thick, between the brick and outer jacket, prevents injury to the iron and radiation of heat into the room The late important improvements do not, however, touch the principles of construction so much as the mode of application.

At first, Mr. Roper placed his air-pump upon the top of the engine, taking the air, by the use of a pipe, through the casing to the firebox. In this way the air became partially expanded before reaching the fire.

In the improved engine he enlarged the air-pump and placed it on the base near the floor, using the coldest air more direct and with much less friction in clearances, by this means obtaining at once nearly double the power by the same size engine.

Next he employed two dampers, one admitting all of the air into the fire-chamber, under the fire-grate, and the other over the fire. The first to be used in time of building the fire, and when it was low, and the other after the fire was complete.

Thus the engine can be started as soon as the kindling wood begins to burn. The pump and check valves are made of leather—very simple contrivances. The bearings and all parts of the engine are made stronger and more durable than at first.

One of the greatest improvements obtained is a perfect governor or regulator. The old governor, which was connected with the air-pump, could not be changed so as to vary the speed materially, and did not hold the engine steady when work was thrown on or off suddenly. The present regulator is not much more or less than a safety valve, placed back of the check, taking air from the pressure, in the generator; and by use of a simple thumb screw, the engine can be made to run with the same power from 40 to 120 revolutions per minute, as required, and that with a steady, smooth, unvarying motion, and nearly as noiseless as steam.

We have examined several of these engines, driving different machinery very successfully, of one, two, and four-horse power; and, by inquiry, we find the amount of coal used is about 40 lbs. per day for a horse power, and that the engines fully show the amount of power claimed.

A one-horse power machine weighs about 2,000 lbs., a two-horse power 3,000, and a four-horse power about 5,000 lbs., so that they are readily moved. No water is required in these engines, there is no boiler to explode, and no extra rates demanded for insurance. A boy can manage one as well as an experienced engineer. The engine is the subject of a number of patents.

All orders or applications for information should be addressed to the Roper Caloric Engine Co., 49 Cortland st., New York city, where the machines may be seen.