The Stirling Engine - By James Stirling

Source: Minutes of proceedings of the Institution of Civil Engineers, Vol. IV, Page 348 - Part 1

Date: June 10th, 1845

Title: Description of Stirling's Improved Air Engine

Author: James Stirling, M. Inst. C. E.

Robert Stirling has been the inventor of the regenerator, which he called himself an economiser, that was a method or mechanical arrangement for diminishing the consumption of fuel.

His brother James Stirling, who built the engine in 1842 in a Dundee Foundry, gives here a detailled description of it, pointing out the economical process. James Stirling also relates the superiority of the air engine against the steam engine.

Mr. Stirling’s air-engine was the subject of a patent dated Oct. 1, 1840, and has been noticed at different times in our pages. We give here the engine presentation made by James Stirling himself read before the Institution of Civil Engineers during the last Session.

Some useful observations relative to the subject of air-engines will be also found in the minutes of the discussion to which the reading of this paper gave rise.

Two well-known attendees participated to the meeting: Sir George Cayley, inventor of the first practical hot air engine, and M. Gordon, inventor of the Fumific Impeller, a hot air engine of specific nature. They both give their point of view in the discussion that followed the presentation of the Stirling engine.

Stirling Engine general description

The principle upon which the movements of this air-engine depend, is the wellknown one in pneumatics, that air has its bulk or pressure increased when its temperature is raised, and diminished when its temperature is lowered.

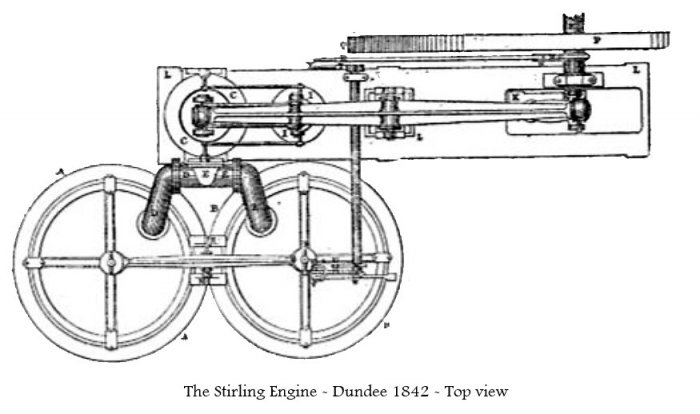

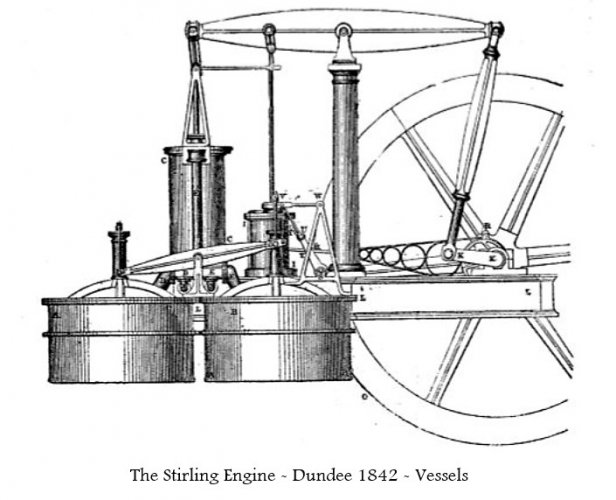

Two strong air-tight vessels are connected with the opposite ends of a cylinder, in which a piston works in the usual manner. About four-fifths of the interior space in these vessels is occupied by two similar air-tight vessels or plungers, which are suspended to the opposite extremities of a beam, and capable of being alternately moved up and down to the extent of the remaining fifth.

By the motion of these inferior vessels, which are filled with non-conducting substances, the air to be operated upon is moved from one end of the exterior vessels to the other, and as one end is kept at a high temperature, and the other as cold as possible, when the air is brought to the hot end, it becomes heated and has its pressure increased, and when it is brought to the cold end, its heat and pressure are diminished.

Now, as the interior vessels necessarily move in opposite directions, it follows, that the pressure of the inclosed air in the one vessel is increased, while that of the other is diminished. A difference of pressure is thus produced upon the opposite sides of the piston, which is thereby made to move from the one end of the cylinder to the other, and by continually reversing the motion of the suspended bodies or plungers, the greater pressure is successively thrown upon a different side, and a reciprocating motion of the piston is kept up. The piston is connected with a flywheel in any of the usual modes, and the plungers, by whose motion the air is heated and cooled, are moved in the same manner, and nearly at the same relative time with the valves of a steam-engine.

This description will be sufficient to show how motion and power are produced, and it is only necessary to add, that the power is greatly increased and made more economical by using somewhat highly compressed air, which is at first introduced, and is afterwards maintained, by the continual action of an air-pump. It may here be mentioned also, that the pump is employed in filling a separate magazine with compressed air, from which the engine can be at once charged to the working pressure.

If all the heat however, which is necessary to raise the air to the required temperature, were to be thrown away or lost every time that the air is cooled, the power produced by its expansion and contraction would be much more expensive than that which is gained by the use of steam.

In order, therefore, to understand how the work of a good steam-engine has been done with about one-third of the fuel consumed by it, it is necessary to point out the method by which the greater part of the heat is preserved, and is used repeatedly, in expanding the air, before it is finally wasted or lost.

The Economiser or Regenerator

For this purpose, when it is necessary to cool the air, after it has been brought to its greatest heat, it is not at once brought into contact with the coldest part of the vessels. This would indeed effectually cool it, but the heat when thus extracted would be entirely lost because it could never again be taken up by a body warmer than itself.

Instead of this, therefore, the air is made to pass from the hot to the cold end of the air-vessel through a multitude of narrow passages, whose temperature is at first nearly as great as that of the hot air, but gradually declines till it becomes nearly as low as the coldest part of the air-vessel. Now as everybody by contact will give out heat to one that is colder than itself, the air, when it enters the narrow passages, must give out a portion of its heat, even to the hottest part of these passages, and must continue in its progress to give out more and more, as the temperature of the passages is diminished, till at last, when it is ready to escape into the cold part of the vessel, there is only a small portion of the heat to be extracted, in order to bring it to the lowest temperature required.

By far the greater part of the heat, therefore, has been left behind, in the metal which forms the passages and which is so contrived and arranged, as to retain that heat until it is again required for heating the air. It must be evident also, from the manner in which the heat has been distributed, or spread out, over the whole length of those passages, that it is capable of being again employed in heating and expanding the air; for when the cold air is again made to enter the passages for the purpose of being heated, it immediately comes into contact with matter that is hotter than itself and consequently begins to acquire heat, even at its first entrance, and as it is successively applied to surfaces of a greater temperature, it continues to receive more and more heat, so that when it comes at last to the hot end of the vessel, it requires but a small addition to its temperature to give it the elasticity which is necessary to move the piston.

Thus, instead of being obliged to supply, at every stroke of the engine, as much heat as would be sufficient to raise the air from its lowest to its highest temperature, it is necessary to furnish only as much as will heat it the same number of degrees, by which the hottest part of the air-vessel exceeds the hottest part of the intermediate passages.

This arrangement or contrivance for the heating and cooling of air and other fluids, which may be termed the economical process, forms the foundation of all the success which has been attained in producing power with a small expenditure of fuel.

This principle was devised and acted upon by Mr. R. Stirling nearly 30 years ago, but until the present time it could not be said to have been beneficially applied to the production of power.

The several means by which the principle is at last rendered effective, consist, chiefly, in the employment of various means for keeping the piston-rods air-tight, and enabling the pressure of the air to be raised to such an extent as to bring the engine into a small compass, and in the introduction of an effective refrigerating apparatus for extracting the waste heat and bringing the air to a lower temperature than could otherwise have been attained.

The greatest difficulty which was encountered consisted, in the proper application of the heat to the outside of the air-vessels. When applied directly by radiation from the fire to the spherical bottom of the vessels, it necessarily heated one part too much and another part too little, and the overheated part was not only liable to rapid oxidation but by its expansion the other parts were strained and cracked.

The heat is now applied chiefly by means of the hot air which passes through the furnace; and it is found that instead of requiring more fuel to keep up the heat, by this method it is accomplished with a considerably less quantity. It is found also that when the flues for distributing the heat over the surface are properly constructed, the air-vessels are very equally heated, and neither show a hurtful tendency to oxidation, nor to that unequal expansion by which the air-vessels might be destroyed.

The two Dundee Stirling Engines

The first engine of this kind which, after various modifications, was efficiently constructed and heated, had a cylinder of 12 inches (approx. 30 cm) in diameter, with a length of stroke of 2 feet (approx. 61 cm), and made 40 strokes or revolutions in a minute (40 rpm). This engine moved all the machinery at the Dundee Foundry Company's works for eight or ten months, and was previously ascertained to be capable of raising 700,000 lbs. one foot in a minute (approx. 21 HP).

Finding this power to be too small for their works the Dundee Foundry Company erected their present engine, with a cylinder of 16 inches (approx. 40 cm) in diameter, a stroke of 4 feet (approx. 1.20 m), and making 28 strokes in a minute. This engine has now been in continual operation for upwards of two years, and has not only performed the work of the foundry in the most satisfactory manner, but has been tested (by a friction brake on a third mover) to the extent of lifting nearly 1,500,000 lbs (approx. 45 HP).

It was found difficult to keep this load steadily applied for any length of time, owing to the strap becoming heated; but the engine has been worked for a whole day with a measured burden of 1,250,000 lbs. (approx. 37 HP), besides driving three extensive lines of shafting 370 feet (approx. 11.3 m) in length; and this work it performed with an expenditure of 1000 lbs. (approx. 454 kg) of Scotch Chew coals, including the quantity necessary to raise the heat in the morning, and to maintain it during the two hours for meals, when the work was usually stopped.

The coals used in this case were of inferior quality, and at least one-fourth less capable of producing heat than ordinary English coals. Taking this into account, and deducting 150 lbs., the quantity which was ascertained to be necessary for raising the heat in the morning, leaves a consumption of 600 lbs. (approx. 272 kg) in 12 hours. But little has yet been done in improving the furnaces, the principal attention having hitherto been devoted to ascertain the best method of heating the air-vessels, without regard to the economy of fuel.

This result, although not so favourable as might be expected is given to show the early capabilities of the engine.

This engine requires only about a cubic inch (approx. 16 ml) of oil to keep the piston and rod in order for two days, and, in consequence of this, the friction of the cylinder and piston is decidedly less than it is in a steam-engine. In like manner the valves of the air-pump and the safety-valves being free from moisture, do not show any tendency to get out of order. The leather collars also are very durable, that of the piston-rod usually lasting about three months, and the others six or nine months; and upon the whole, the working of the machine, besides the saving of fuel, is altogether more economical and less troublesome than that of a steam-engine.

It has been already stated, that the air is worked at a high pressure, sometimes rising at its maximum to 16 atmospheres, and it may perhaps be thought by those who have attended to the many accidents that are perpetually occurring from the use of high pressure steam-engines, that the employment of the air-engine must be dangerous. A little consideration of the subject, however, will be sufficient to quiet all such apprehensions, and to show that there is less liability to explosion than in steam-engines of almost any description.

Comparison with Steam Engines

In the case of a steam-boiler, it is well known that a small addition of temperature gives a vast addition to the elastic force of its contents, and consequently, when the safety-valve fails to act, if the application of heat be continued for a very short time, the internal pressure is increased to an immense amount. Besides, when an explosion takes place in a steam-boiler, there is not only a great quantity of steam already formed, which expands, and spreads destruction around, but a large portion of the water, when the pressure is removed, flies up in the form of steam, and greatly extends the devastation.

In the air-engine, on the contrary, it is next to an impossibility to produce an explosion. The furnace must be so constructed for the safety of the air-vessels, that no great change in their temperature can be suddenly brought about, while it requires a great addition to the temperature of the air to make any considerable addition to its pressure.

On the other hand, the forcing in of air by the air-pump is a very slow process, and as it is always adjusted so as to supply no more air than is sufficient to keep up the desired pressure, whenever a little addition is made to that pressure, it increases the unavoidable leakage to such a degree, that the further accumulation of air inevitably ceases. And while on these accounts it is not possible to increase the pressure of the air to the extent of one-fourth, the vessels are proved to the extent of double the maximum pressure, and are calculated to resist three or four times as much.

Nay, even if such a thing as an explosion were to take place, it could not be attended with the disastrous consequences which attend the bursting of a steam-boiler, since the air, though allowed to expand to the utmost, would not amount to more than 20 or 25 times the bulk of the cylinder; indeed, in the early experiments such innocuous explosions were more than once witnessed.

Besides, almost all explosions of steam-engines take place when the machine is at rest, while the air-engine, by the very act of stopping, has its maximum immediately reduced to the mean pressure, which is afterwards further diminished by leakage, and it cannot be again brought up unless by the slow operation of the air-pump, or the deliberate act of the engineer in letting in more air from the magazine, in which he is always guided by an indicator.

It may be supposed, that though the air-engine has worked well when placed under the inspection of experienced engineers, it will be liable to get out of order, or to become altogether unmanageable, when committed to the care of an ordinary fireman. But although, for the inventor's satisfaction, a skillful mechanic was kept in attendance for a considerable number of months, in order that every possible contingency might be observed and provided for, the engine is now committed to the charge of the same person who used to keep the steam-engine, and it is found to be equally simple and easy in its management, and sure and steady in its operation.

The Hot Air Engine will soon have a bright future

After the statement of these facts and explanations, it is not surprising that sanguine hopes should be entertained of the air-engine's coming speedily into general use as a moving power. It has already been successful to such an extent as to afford a powerful inducement to the use of it, wherever fuel is a matter of serious consideration. Even where the price of coals is lowest, the saving that would be accomplished by converting a steam-engine into an air engine, would afford a fair return for the expense of conversion — much more profitable then must it be, when a moving power is required for a new establishment; but where the price of coals reaches, as it does in many parts of the world, to 20s. per ton or upwards, it would seem to be a matter of unquestionable propriety to make use of a power that can be maintained at about one-third of the present expense.

It would be needless, in its present state, to speculate on the probable results of the introduction of this engine for marine purposes. There, every ton of fuel that is saved is not only a direct gain to the extent of its market price, but in long voyages an indirect gain is effected of at least twice as much more, from the increased accommodation which it allows for the carriage of merchandize. Nay, when the value of time is so well understood as at present, or when the rapid communication of intelligence is a matter of such importance, surely no slight objection ought to prevent the employment of any means by which a ship may be enabled to hold on her course without interruption, for twice or thrice the length of time she now does.

The Stirling Engine and further improvements

Many other improvements in the construction of the engine have suggested themselves during its progress, but which the serious expense of alterations has alone hitherto prevented the author from putting to the test — such as the introduction of valves, for relieving the working parts of the engine from the pressure during the time the crank is passing the centres, etc.; but the hope of the perfect success of the engine, and particularly of its successful application to the propelling of ships, is principally founded on the fact that the powers of the economical process, which theoretically appear to be infinite, are not yet practically nearly exhausted.

It was perceived from the beginning, that in order to render the heating and cooling of the air complete and economical, it would be necessary to make the passages through which it is conveyed from the one end of the air-vessels to the other, as narrow as possible. This is rendered necessary by the very defective conducting power of air, and the consequent difficulty of heating and cooling it. But on the other hand, the contraction of the passages, in which the air is heated and cooled, greatly increases the force which is necessary to pass it through them, so that, if they were made extremely narrow, the whole power of the engine might be consumed in transferring the air.

Elementary experiments could not be trusted nor did there exist any theoretical calculations to determine the minimum width and length to which the passages might be reduced with advantage, and the proceedings have hitherto been by slow and cautious steps towards a practical determination of this problem. Each engine that has yet been constructed, has been improved by the contraction of its passages after a first trial and there has been a decided improvement, both in power and economy, by these means.

There is no reason to believe that the maximum of effect, from the contraction and shortening of the passages, has yet been attained; and it may be expected, that the next engine that may be constructed, will be considerably improved in these particulars. A considerable increase, both in power and economy, may be anticipated from a more perfect application of the heat to the outside of the air-vessels — a matter in which the advances must be by still more slow and cautious steps.

In short, when it is considered how much has been already accomplished in what may be termed a first trial, and how much more is evidently possible, no doubt can be entertained that the air-engine will soon be adopted as a moving power.