The Woodbury atmospheric Engine of 1853

In 1853 hot air engines were still not used on an industrial scale. Ericsson's caloric ship engine failed to demonstrate its superiority to the steam engine be it on the fuel consumption side or and the technological side, and showed many of the hot air engine weaknesses, especially their poor durability.

Woodbury & Co. goal was to build an atmospheric hot air engine, means an engine that uses the atmospheric air as a propelling agent by the application of heat (Woodbury & Co. were speaking of the application of the "caloric"). Their engine principles are different than Stirling's or Ericsson's.

However, the terminology "atmospheric" is somewhat debatable. The engine is rather an external combustion hot air engine.

Woodbury & Co. filled two patents in 1853, the second one being a major improvement of the engine presented in the first one.

Rediscoveries through practical experiments

A fact largely admitted at that time was that air, when under the influence of about 480 °F (around 249 °C) of heat, becomes expanded to double its original volume.

At that time a fact largely admitted was that air at 32 °F will double its original volume when under the influence of about 480 °F (around 249 °C) of heat. Today we would use temperature in Kelvin and say that in case of constant pressure the temperature is doubled, then the air volume will double too. An explanation of this fact is given ! here XXX.

Regarding their engine the Woodbury & Co. wanted to verify what would happen to pressure if the volume remained constant.

Through practical experiments they came to discover that if air is highly compressed in a receiver and then heated to about 480 °F, its expansion force will increase to double the force exerted by the same air prior the application of heat. In other words, with the application of heat at 480 °F, if the pressure remains constant, the volume will double, or if the volume is constant then the pressure will double.

Again, using Kelvin we would say in case of constant volume that the air pressure will double if the temperature doubles. Surprisingly these gentlemen inventors did not know the Law of Charles discovered in 1787, and had to do experiments to rediscover it ! They considered being worth to mentioned the fruits of their experiments in their patent.

Now these experiments led them to another important conclusion that gave base to the working principle of their engine. But let's them do the talk :

We have ascertained by practical experiments, that if air be highly compressed in a receiver and then subjected to about 480 ° degrees of heat, that its expansive force will be increased to double the amount exerted by the same prior the application of heat. Thus it will be perceived that by increasing the amount of air forced into the receiver, the pressure it exerts can be doubled by the same constant degree of heat above stated, whatever may be the pressure exerted in the first place, by the cold compressed air, the degree of pressure which can be attained, depending entirely upon the density of the compressed air, while the amount of caloric applied remain the same.

A new working principle

Woodbury & Co. were aware that atmospheric and gas engine had long been known. But the way they use the air as a motive power was new.

A first way is to use highly compressed air as a motive power, in which no heat is used. Another mode is done by engine that air has been heated, expanded, cooled and contracted after the manner of a low-pressure or condensing steam engine. This is the case of the Ericsson engine. A third mode is the one of the old Stirling engine where compressed air is used, heated and cooled in cycle in its passage through the engine ; the air being also the working fluid. The same air is used over and over.

In the Woodbury atmospheric engine the highly compressed air is in a receiver and heated up. A uniform pressure is maintained in said receiver with the help of an air-pump which is about one-half of the volume of the working cylinder. The heated compressed air is expanded alternatively upon opposite sides of a piston after the manner of a common high-pressure steam engine.

An important part of the invention is the regulation of the cut off of the heated air during its expansion that must be done accordingly to the compression of the air.

Description

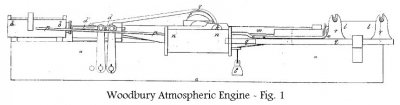

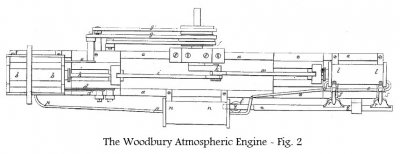

The essential parts of the Woodbury atmospheric engine consist of a working cylinder (b, b), an air pump, and a receiver (Fig. 1 et Fig. 2). The cylinder (b ,b) is of the same construction as an ordinary steam engine with a supply and a discharge valve. The two valves are worked respectively by the valve rod ( d, e) and connected to the eccentrics (f, g). The piston rod (h) and the connected rod (i) are attached to the crank k. The cut off valve is worked by the rod (d') and the eccentric (g') the same way as in a steam engine.

The cylinder (b ,b) is of the same construction as an ordinary steam engine with a supply and a discharge valve. The two valves are worked respectively by the valve rod ( d, e) and connected to the eccentrics (f, g). The piston rod (h) and the connected rod (i) are attached to the crank k. The cut off valve is worked by the rod (d') and the eccentric (g') the same way as in a steam engine.

The air pump (l, l) is double acting and is half the volume of the working cylinder. It is worked by a connecting rod (m) also attached to the crank k. An additional mechanism prevented the pressure of the compressed air to become too great.

The receiver (n, n) contains the compressed air. It communicates with the pump by the pipe (o, o) and with the working cylinder by the pipe (p, p).

Unlike most hot air engines, the Woodbury atmospheric engine had no flywheel. If we consider the evolution of the engine and the result achive in hte one of 1880, we can here conclude a mistake.

The engine is an open-cycle external combustion hot air engine (Fig. 1 and Fig. 2). However, in their improvement of the same year (Fig. 3), the engine is a closed-cycle one. Rather than a contradiction, it is an evolution. The inventors aiming at high power enignes, come to the conclusion that this can be achieved only through closed-cycle engine.

Same type of evolution will be seen for other features.

Operation

To start the engine heat at 480 °F is applied to the receiver containing air at atmospheric pressure. The air pressure will double and then will be communicated to the working cylinder and operate the piston. There it will exert sufficient force to start the engine.

Motion is imparted to the piston of the air pump which is drawing its supply from the atmospheric air (whence the name atmospheric engine). The pump forces a quantity of cold air into the hot receiver. Due to the action of the heat, this cold air will immediately double its pressure. It will then go to the working cylinder to start a new cycle.

The supply of hot air into the working cylinder will be cut off at proper time, the cutting off depending upon the degree of compression of the air.

The economizer

In their improved variant (Fig. 3) the engine receives an additional exhaust cylinder (q, q) that which purpose is to reuse the heat of the expanded air. It works like the economizer (or regenerator) of the Stirling engine.

The piston from the working cylinder is started by air delivered from the receiver as for the first variant. But the exhaust air, instead of passing out into the atmosphere, is conducted through the pipes (p, p) around the flues of the exhaust cylinder (q, q) and through the pipes (r, r) to the reservoir (n), from which it is delivered to the air pump to be again compressed.

The compressed air passing from the pump to the heated receiver (k, k) is conducted through the pipe (s, s) to the exhaust cylinder (q, q) through the flues of which it is heated by the exhaust air passing around them.

Discussion

The way they built their engine tells that Woodbury & Co. understood the paramount importance of separating the working fluid heating phase with its expansion / compression phases. They suggest in their patent that the receiver, instead of being horizontal could be set up in a vertical position, the receiver having interior pipes or flues like a common boiler. Heating time and heating surfaces, this is all what the Stirling engine or the Ericsson engine did not have.

Between the first and the second variants, that happened within a few months, notable modifications are visible. The inventors, learning fast, understand that atmospheric pressure will generate only low power and do the necessary transformations in order to use compressed cold air in their engine. This imply a move toward a closed-cycle engine.

They also add the exhaust cylinder that works like the economizer of Rev. Stirling's engine in order to reuse lost heat.

These three parts (heater, close-cycle with high pressure and economizer), although still not a very matured concept, but was certainly the first step towards their major innovation : the reverser of the 1880 engine.

One of the major flaw of this atmospheric engine is the injection of air into the receiver. There is obviously a difference in pressure between the cold air coming out of the pump and the heated air inside the receiver, the pressure of the latter (as planned by Woodbury & Co.) being double of the incoming air. This is physically not possible. In order to enter the receiver, the incoming air must be at the same pressure as the air inside the receiver.

Therefore at each cycle, the pump has to increase the cold air pressure, and as a consequence the volume of the cold air decrease cycle after cycle. After a while the engine has not enough air to work anymore and will stop.

Inventors have often done this mistake because they followed blindly the principles of the steam engine. The Woodbury & Co. next engine will magnificently address this issue.

The removal of the flywheel is a doubtful feature because the issues deriving from the deads ends are not otherwise addressed. The engine can start by itself only if the crank is positioned manually in an appropriate way. Any stoppage can become cumbersome. Moreover, even if the engine starts by itself, it is highly probable that it will run roughly and irregularly due to the lack of inertia that the missing flywheel can not give.

In their next engine, the inventors will add a flywheel.