John Ericsson

Source: Motor Boating

Title: Ericsson's Dream - The story of Captain John Ericsson's attempt to supplant the marine steam engine by his caloric or hot air engine

Author: Commander W. Mack Angas

Date: July 1938

Supersede the Steam Engine

Captain John Ericsson, 1803 - 1889, was born in the province of Wermland, Sweden.

The golden age of the American merchant marine was the period of the sailing ship which reached its zenith before the Civil War. The designers and builders of the great Yankee clippers of this era were world-famous for their skill, such men as Donald McKay being remembered today for the wonderful sailing vessels they produced.

Similarly the naval architects and marine engineers of the United States played important roles in the development of the steamship, for the first commercially successful steam vessel and the first ocean-going ship to be fitted with steam engines were products of American enterprise.

Furthermore in the early fifties the New York-built Collins liners were the first steamships to offer comfort and even luxury to their passengers rather than mere transportation, and in their day were the finest steamers afloat. At this time, when Yankee clippers and the fast ships of the Collins line were supreme in their respective classes of ship, there was no bolder, more inventive, or ingenious marine engineer than John Ericsson, the Swedish-born New Yorker who had already made himself famous by the successful application of the screw propeller to ocean-going vessels and was later to influence the history of his adopted country profoundly by producing the Monitor at one of its most critical periods.

Throughout the forties Ericsson clearly saw the need for engine-driven vessels capable of longer voyages than could be made by steamers without refueling. He was also appalled at the only too numerous marine boiler explosions that were then doing much to shake the confidence of the public in the steamboat and steamship.

Although the science of thermodynamics was then in its infancy, Joule not having completed his researchers into the mechanical equivalent of heat, Ericsson also realized that the steam engine and boiler were fundamentally devices for converting heat into mechanical work and that to produce steam in a boiler and then expand it in the cylinder of an engine was a clumsy and indirect way of going about this conversion.

Experiments made from time to time over a period of over twenty years led him, in the late forties, to the conclusion that the twin goals of economy and safety could be achieved by completely eliminating the boiler and substituting for the steam engine, the hot air, or as he preferred to call it, Caloric engine.

Though the engine he built for the caloric ship which bore his name was not successful, the large scale with such machinery is worth a brief review, not only because of the boldness with which it was executed, but because his insistence that the boiler should be eliminated is today being vindicated by the rapidity with which the motor ship is developing.

It would be an absurd over statement to say that Ericsson in any way anticipated the internal combustion engine when he built the machinery for the caloric ship. His engine was distinctly an external combustion engine when he built the machinery for the caloric ship. His engine was distinctly an external combustion engine, but he at least took one step away from steam by placing his furnace under the cylinders that drove his ship instead of having them under a boiler.

Who knows but that if liquid fuels had been available he would have taken the final step of having the fires inside the cylinders instead of under them? But that is surmise; the facts are interesting enough.

The first Hot Air Engines

Ericsson did not originate the idea of using the expansive force of heated air to run an engine.

In 1797 Glazebrook took out an English patent on a engine consisting of two cylinders of unequal size, the pistons of which were connected to opposite ends of a walking beam. Air was compressed in the smaller cylinder, was then heated by passing it through a pipe coil in a furnace, and was finally expanded in the larger working cylinder. Quoting Knight's Mechanical Dictionary:

His engine was of the differential order, and he states the measure of power to be the difference of force exerted in the working and compressing cylinders, of which the latter is much the smaller, and the extra force in the former is due to the accession of heat derived from the furnace wherein the air is heated after compression in the smaller cylinder, and before it is admitted to and allowed to expand against the piston in the larger cylinder. Viewing the history of the air engine for seventy years succeeding Glazebrook we may at least say he was a great anticipator.

In 1819 Lilley took out an English patent on a somewhat similar engine.

Ericsson's interest in the hot air engine appears to date from the early eighteen-twenties when in Sweden he constructed a flame engine, as he called it, of several horsepower. This machine he described in a paper written in Swedish entitled, "A description of a New Method of Employing the Combustion of Fuel as a Moving Power."

A copy of this paper was sent to the newly organized "Institution of Civil Engineers" of London, and in 1826 young Ericsson took a model of his engine to London in the hope of promoting its adoption as a competitor of the steam engine. However, the machine did not run as successfully with coal fuel as it had done in Sweden with wood and Ericsson turned to other fields of engineering activity to earn his living in London.

He did not lose interest in the hot air engine while busy with other things, and still believed it to be fundamentally a better device than the steam engine for converting heat into work. He was also on guard lest some other inventor take advantage of the researches he had made and the effort he had expended in attempting to develop a practical hot air engine, and in the year of his arrival in London (1826) opposed the granting of a patent to Robert Stirling on an engine of this general type.

Stirling's patent was granted in spite of Ericsson's claims to priority. It covered an engine in which air was alternately heated and cooled in a closed vessel, the resulting expansion and contraction of the air being used to actuate a piston in a separate working cylinder. The heating and cooling were effected by driving the air from one end to the other of a cylindrical vessel by means of a loose fitting piston or displacer, one end of the vessel being heated by a furnace and the other end cooled by a water jacket.

A few Stirling engines were built and used in Scotland, one being installed as a marine engine on the Highland Lad, and though they were more economical than contemporary steam engines in so far as fuel consumption was concerned they were also heavier and more bulky for the power developed and were much more prone to break down. In particular it was found difficult to keep the pistons tight and properly lubricated at the relatively high temperatures at which the engines worked, and the parts of the engine exposed directly to the heat of the furnaces also burned out rapidly and required frequent renewal.

In spite of their high fuel economy, the engines were not a success and were replaced by steam engines.

The Ericsson Caloric Engine of 1833

The granting of Stirling's patent did not deter Ericsson from further experimentation and research with hot air engines and in 1833 he built and exhibited in London an engine having a double-acting working cylinder 14 inches in diameter which developed five horsepower and worked on the cycle advocated by Glazebrook.

To the original conception of Glazebrook, Ericsson added a device which he called a regenerator. It consisted of a number of copper tubes through which the air passed on its way from the compressing cylinder to the heating unit in the furnace. The exhaust from the working cylinder passed around these tubes, transferring some of its heat to them and thence to the incoming charges of air, thus to a considerable extent improving the economy of the machine.

The engine, like other hot air engines, had a relatively high thermodynamic efficiency, but much trouble was experienced with the lubrication of the cylinder and valves. Mineral lubricants such as are now used in the cylinders of internal combustion engines and high pressure steam engines were then unknown, and it is not surprising that trouble occurred with tallow-lubricated pistons and cylinders working at temperatures of 450 degrees F.

In 1839 Ericsson came to New York, making the Atlantic voyage on Great Western in the stormy month of November and suffering frightfully from seasickness during the greater part of an exceptionally rough twenty-two-day passage. It does not appear that he originally intended to settle in America, but the progressive spirit of the country made a strong appeal to him and offered great opportunities to a man of his energy and unique gifts.

Throughout the forties he was busy with the promotion of the screw propeller in the United States, with the design and construction of the U.S.S. Princeton, and the development of a successful steam fire engine. He found time, however, for further experiments with hot air engines and in the forties constructed several such engines in New York.

Ericsson's Caloric Ship

The largest of these was a two-cylinder single-acting beam engine with working cylinders 6 feet in diameter and a stroke of 2 feet. The economy of this engine was so high - Ericsson reported it capable of developing a horsepower hour on eleven ounces of coal - and its performance so satisfactory that the inventor was encouraged to carry out his long cherished scheme of fitting an ocean-going vessel with a larger engine of the same general type.

Though these engines were, strictly speaking, hot air engines, Ericsson himself always preferred and used the somewhat meaningless term, caloric engine.

A group of New York merchants and financiers headed by John B Kitching, Edward Dunham, President of the Corn Exchange Bank, and G.B. Lamar, president of the Bank of the Republic, backed the project and in April, 1852, the keel of the ship was laid at the yard of Perine, Patterson, and Stack in Williamsburgh. At about the same time the construction of the engine was commenced by Messrs Hogg and Delamater.

Hull and machinery were built in the greatest possible secrecy, both Ericsson and his financial backers being convinced that their ship would revolutionize ocean transport by its economy and safety, and that competitors would if possible copy the design of at least the engine.

On September 15, 1852, the ship was launched and in November the engine was turned over at the dock under its own power.

Interest in the unusual vessel was naturally keen, Ericsson's reputation as an engineer leading the general public and non-technical press to place great faith in the success of the enterprise. The technical press was more conservative, pointing out many of the obvious difficulties that lay in Ericsson's path. The Scientific American in particular had little faith in the undertaking and published several articles attacking the soundness of many of the assumptions made by admirers of inventor.

Said this magazine; "Some have got the idea from the name of an apparatus connected with the air engine that no heat will be lost, that the same heated air will be used by some hocus pocus over and over again to drive the engine without extra combustion. It is just as scientific thus to talk of using heated air as to expect water to run down hill to drive one water wheel, and then up another to leap down a second fall to drive a second wheel."

In fairness to Ericsson's memory it should be made clear that he never made or countenanced many of the claims for the caloric engine made by his non-technical friends. From some of their statements it might be inferred that the engine was practically a perpetual motion machine, using the same heat over and over again to generate power, and requiring only a small amount of heat from its furnaces to make good radiation losses. The fact was that Ericsson claimed to have so greatly reduced the heat loss with the exhaust of his engine that, with the exception of the losses due to radiation, practically all the heat generated in the furnaces was converted into useful work.

Subsequent events were to prove even this claim an ex-aggregation, but there is some excuse for Ericsson making it as the important discovery of Carnot, that the efficiency of a heat engine depends upon the temperature range through which it works, had not been widely published or generally accepted. While a fine little controversy raged as to whether the ship would prove economical, even as to whether or not she would run at all.

Ericsson worked almost night and day to get her finished. No matter what his critics may have thought of him as a scientist, engineer, and inventor, even his worst enemies must have admired his ability to get things done. The construction of the caloric ship in less than ten months was an example of this ability.

On February 4, 1853, she made a trip to Sandy Hook and back to try out her machinery and a week later, on the 11th, came the long awaited day when the inventor and his associates invited representatives of the press to inspect the ship, and in fact to make a trip on the Bay in her.

The guests who boarded the Ericsson, as the vessel was called, on the morning of the 11th of February found her to be a beautiful and fine lined side wheel or paddle boat 260 feet long overall, with a beam of 40 feet, and a depth of hold of 27 feet. She drew 17 feet of water as loaded for the trial trip. Her side wheels were 32 feet in diameter. She had two masts, both square-rigged, and four small stacks arranged in pairs abreast, one pair ahead of the shaft and the other abaft it. It was explained that one stack of each pair was a smoke pipe from the furnaces of the engine and the other an exhaust pipe.

There was admiration for the ship's spacious and taste fully decorated staterooms and saloon, for the large freight deck made possible by the small coal bunkers, and for the elaborate ornamental device on the stern, representing to quote the Courier and Enquirer, "the figure of the inventor with allegorical figures representing the United States and Great Britain in the act of binding a wealth of laurels around his brow." But it was to the engine room that the curious guests gravitated and the inventor himself was stationed there to answer questions and explain the working of the unique power plant.

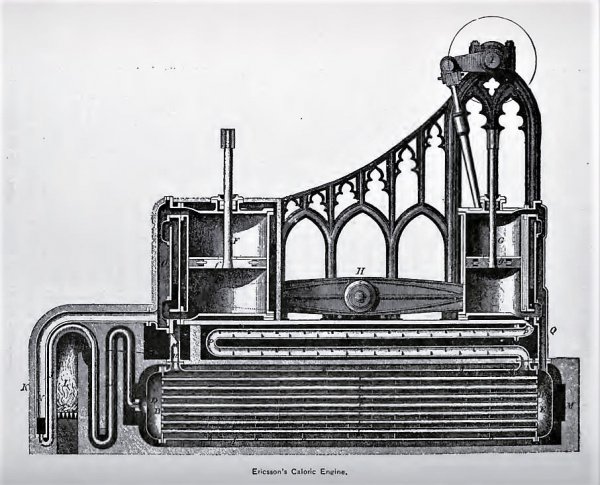

The engine had four single-acting vertical cylinders, arranged in pairs, one pair forward and one abaft the paddle shaft. These cylinders were mounted directly over the furnaces on the center line of the ship and were of altogether unprecedented size, their bore being 14 feet and stroke 6 feet. the working pistons, the upper surfaces of which could be seem through the open tops of the cylinders, were connected by links to the ends of two walking beams, one of which was supported on trunnions between each pair of cylinders.

The motion of the walking beam was communicated to a single crank on the paddle shaft by two connecting rods which made an angle of about 90 degrees with each other. Inverted over the working cylinders and walking beams were charging or supply cylinders which had a diameter of 11 feet, 5 inches. The piston of each charging cylinder was connected to the piston of the working cylinder below it by means of eight wrought iron rods. The cycle of operation was as follows: Air was drawn into the charging cylinder through valves in its piston, was compressed in that cylinder to a pressure of about 12 pounds per square inch, and then passed to a receiver where it was stored at that pressure. From the receiver it passed to the valve chamber of the working cylinder.

A mechanically operated inlet valve in this chamber admitted the compressed air to the heated working cylinder at the bottom of the piston stroke, the air taking up sufficient heat from the bottom head of the cylinder to expand without any appreciable loss of pressure, thus raising the working piston to about 6/10 stroke, at which point the inlet valve closed permitting the stroke to be completed by expansion of the air already in the cylinder. At the top of the power stroke the exhaust valve opened allowing the air to escape to the atmosphere as the piston descended. Between each valve chamber and the cylinder it served was a regenerator consisting of a chamber packed with 50 thicknesses of metallic screen wire.

The outgoing exhaust gave up a considerable quantity of its heat to this wire at each stroke and as the next incoming charge of air for the working cylinder passed through the same wire it acquired form it a large part of the heat recovered from the exhaust. The engine was started by pumping air into the receiver with a small engine and air compressor until the pressure was sufficient to operate the main pistons. Maneuvering was accomplished as in the marine steam engines of the day by disconnecting the eccentric rods and operating the valves by hand gear.

As the ship started down the Bay the guests were delighted with the smooth working of the machinery. The engine was stopped for a short time during the trip and a few of the more daring spirits accepted the inventor's invitation to "step abroad the pistons and take a ride". With several men on two of the 14-foot pistons the engine ran for a couple of minutes while they enjoyed the novel experience of riding on the working pistons as the big engine ran. When the ship reached the middle of the Upper Bay she met the Collins Liner Baltic coming in from Europe and exchanged salutes with her. Speaking of this incident the Mirror said "The steamer passed inland, as though conscious of her coming fate; while the breathing ship, quietly contracting and expanding her lungs, passed seaward, as though she, too, was conscious of her opening and magnificent destiny."

Off Staten Island the Ericsson turned homeward and the guests gathered to hear an explanation by the inventor of the way in which the caloric engine worked, a cardboard model of the machine being used to make everything clear. Ericsson then answered numerous questions and stated he was confident that the major troubles predicted by critics of his engine would never occur.

To begin with, he said that though the bottom heads of the working cylinders were exposed directly to the fires of the furnaces, they were of boiler plate 1½ inches thick, well able to stand long exposure to the radiant heat of a slow-burning anthracite fire five feet below them. He estimated the cylinder heads to be good for at least four years' service. Lubrication troubles were minimized by the 6-foot thickness of the hollow working pistons which were packed with an insulating mixture of charcoal and plaster of Paris so that the packing rings at the tops of the pistons were always cool though the bottoms of the pistons were exposed to air at high temperature.

The consumption of coal by the four double furnaces of the ship he estimated to be six tons per day as against the 50 tons burned by contemporary ocean liners. The cylinders, he admitted, were not as large as he had wished. His calculations called for 16-foot cylinders, but iron founders had been unwilling to undertake the casting and boring of cylinders larger than 14 feet. Happily, however, the manufacture of the 14-foot cylinders had given to little trouble that their makers were now willing to undertake at their own risk the casting and machining of cylinders up to 24 feet in diameter so that future caloric ships would have power equal to that of the swiftest steamers.

As the Captain finished his explanation and discussion the ship dropped anchor off the Battery and the guests adjourned to the dining saloon where a cold luncheon, speeches, and resolutions were indulged in.

On the following day the New York press was hardly less laudatory than had been the speakers at the luncheon abroad the Ericsson.

The Tribune, which had been represented on the trial trip by Charles A. Dara, opened its account of the trial trip as follows: “We were present yesterday at the second trial trip of the Caloric ship Ericsson; and are prepared to say without hesitation or reserve, and not merely on our own judgment, but on that of every gentleman in the company, that it proved utterly and beyond possibility of doubt the existence of a new motive power as sure and efficient as steam, while it is free rom all danger of accident, and is vastly cheaper and more manageable. The demonstration is perfect. The age of steam is closed; the age of Caloric opens. Fulton and Watt belong to the Past; Ericsson is the great mechanical genius of the Present and Future.”

In the lavish praise heaped upon inventor and ship by practically all the responsible newspapers of New York and the other large eastern cities, the warnings and doubts of conservatives were scarcely noticed, or were brushed aside as the propaganda of boiler-makers and steam engine builders.

The Scientific American courageously denied, however, that anything more had been proved than that the ship could make short trips at moderate speed, pointed out that the speed of the Ericsson had been nearer eight miles an hour than the ten or twelve reported by many newspapers, and further showed that the coal consumption of six tons a day when compared with the fifty-ton consumption of the big Cunard and Collins liners was not very remarkable if due allowance were made for the differences in the size and speed of the vessels.

The Journal of the Franklin Institute also expressed doubts of the validity of many of Ericsson’s claims. The controversy that preceded the trial trips of the ship was nothing to the one which followed the newspaper accounts of the trip of February 11, and all parties to the controversy eagerly awaited the ship’s first sea voyage to demonstrate the validity of their views.

This voyage was made in the latter part of the February when the Ericsson started for Washington. Commander Joshua Sands accompanied her and reported enthusiastically to Secretary of the Navy John P. Kennedy on the performance of ship and machinery in a letter dated February 23.

On the following day Ericsson addressed a letter to the Secretary proposing the construction of two ships of war of not less than 2,000 tons burden to be driven ten miles an hour by caloric engines on a consumption of not more than eight tons of coal a day. Secretary Kennedy immediately laid the matter before the chairman of the House Naval Committee in a letter recommending an appropriation for the construction of one such vessel, but the committee was not to be rushed and prudently decided to await further developments.

The further developments were not long in coming and were a rude shock to the admirers of Ericsson and the caloric ship.

The vessel returned to the yard of the builders in New York where it was announced that certain indicated modifications and improvements were to be made to the machinery. Again a veil of secrecy was thrown around all activities concerning the ship, but the magnitude of the changes under way could not long be concealed.

The news leaked out that the huge low pressure caloric engine was a complete failure in spite of the eulogies of the press. It could not drive the ship at more than five or six knots at sea and required such extensive repairs after the short voyage to Washington that it was being removed from the ship. In particular the bottoms of the working cylinders had been so badly burdened, buckled, and distorted by the heat of the furnaces that complete replacement was necessary, and furthermore a great deal of trouble had been experienced with lubrication when the engine became thoroughly warmed up by continuous operation for seventy hours or more. Only by the use of prodigious quantities of tallow had the engine been kept running on the return trip from Washington.

Ericsson was convinced, however, that the principle of the engine was not at fault and persuaded his financial backers that the construction of an improved engine was justified.

The new machine had two double-acting cylinders only 6 feet in diameter with a stroke of 6 feet. These were supplied with air at relatively high pressure by charging cylinders, the air being heated by passage through pipe coils in the furnaces on its way rom the charging to the working cylinders The machine thus resembled very closely the experimental engine built in London in 1833 except that much higher pressure were used.

A trial trip on New York Bay was made with the new engine on March 15, 1854, and on April 27 of the same year a second trip was made, the outcomes of which is best told in the words of a letter written by the inventor the following day. This is quoted from Church’s Life of John Ericsson.

At the very moment of success - of brilliant success - fate has dealt me the severest blow I ever received. We yesterday went out on a private preparatory trial of the caloric ship, during which all our anticipation were realized. We attained a speed of from twelve to thirteen turns of our paddle-wheels, equal to full eleven miles an hour, without putting forth anything like our maximum power.

All went on magnificently until within a mile or two of the city (on our return from Sandy Hook), when our beautiful ship was struck by a terrific tornado on our larboard quarter, careening the hull so far as to put completely under water the lower starboard ports, which unfortunately the men on the freight deck had opened to clear out some rubbish, the day being very fine. The men, so far as we can learn, became terrified and ran on deck without closing the ports, and the hold filled so rapidly as to sink the ship in a few minutes.

I need not tell you what my feelings were as I watched the destructive element entering the fireplaces of the engines, and as the noble fabric, yielding under my feet disappeared inch by inch. A more sudden transition from gladness and exultation to disappointment and regret is scarcely on record. Two years of anxious labor had been brought to a successful close, the finest and strongest ship perhaps ever built was gliding on the placid surface of the finest harber in the world and within a few cable lengths of her anchorage; yet with such solid grounds for exultation, and with such perfect security from danger, a freak of the elements effected utter annihilation in the space of a few minutes.”

With characteristics energy Ericsson set to work to raise his ship and four days after the accident he had the vessel in dry dock at the Navy Yard in Brooklyn. After a thorough examination he reported that the estimated cost of repairs to the machinery was $12,000. Perhaps he knew at last that his plan for the revolutionizing of marine engineering - a plan on which he and his associates had spent upwards of $350,000 - was a failure, perhaps the financial backers of the scheme had finally wearied of the gibes of friends who had long been making fun of “the group of hard-headed Yankee businessmen who had sunk a fortune in a crazy invention” as they put it.

At any rate the caloric engine was removed from the Ericsson and she was fitted with steam engines with which she rendered useful service, first as a transport and then as a gunboat in the Civil War. She ended her days as a sailing ship under the British flag.

Ericsson himself finally realized that the caloric engine was fundamentally unsuited for construction in large sizes, and that it could never complete with the steam engine as the motive power for large ships. In summing up his account of the construction of the Ericsson and her machinery in his “Contributions to the Centennial Exhibition” he said:

The average speed at sea proving insufficient for commercial purposes, the owners, with regret, acceded to my proposition to remove the costly machinery, although it had proved perfect as a mechanical combination. The resources of modern engineering having been exhausted in producing the motors of the caloric ship, the important question has forever been set at rest: Can heated air as a mechanical motor complete on a large scale with steam? The commercial world is indebted to American enterprise - to New York enterprise - for having settled a question of such vital importance.

The marine engineer has thus been encouraged to renew his efforts to perfect the steam engine, without fear of rivalry from a motor depending on the dilation of atmospheric air by heat.

Smaller Caloric Engines

Ericsson did not, however, altogether abandon the hot air engine but succeeded in developing it into a thoroughly practical and useful small motor for driving domestic pumping machinery and for running light machinery such as printing presses. Until the development of the practical internal combustion engine Ericsson hot air engines were to be found in farms, villages, and country estates all over the world rendering valuable service to their owners and to some small extent vindicating the theories of their distinguished inventor.