Ericsson's Caloric Engine of 1851

Source: The American Journal of Science and Arts, 2nd series, Vol. XV

Date: May, 1852

Title: Ericsson's Hot Air or Caloric Engine

Author: William A. Norton, Professor of Civil Engineering in Yale College

A short notice of this new engine, containing a description of its construction and working, was published in the last number of the Journal; it is proposed, in the present communication, to enter upon a somewhat extended discussion of its theory and performance.

The notice referred to describes the stationary test-engine of 60 horse-power, which was set up in the manufactory of Messrs. Hogg & Delamater, New York; in the present inquiry I shall confine my attention chiefly to the enlarged and modified form presented in the engines of the caloric ship Ericsson.

These engines consist of four large double cylinders, "standin a fore-and-aft line ; two before and two abaft the shaft of the paddle wheels, and working in pairs upon it." Each cylinder is double, the two cylinders being placed one above the other.

The lower one, which is the larger of the two, is called the working cylinder, and the other the supply cylinder. The working cylinder is entirely open at the top, and the supply cylinder at the bottom. The pistons which play in the two cylinders are connected by eight strong iron columns, and move up and down together; the length of the stroke is therefore, of necessity, the same for each, viz : 6 feet.

For the sake of distinction, the piston in the working cylinder is called the working piston, and the piston in the supply cylinder the supply piston. Underneath each working cylinder is a furnace, which heats the air in this cylinder beneath the piston, and by thus increasing its expansive force, furnishes the motive power of the engine.

The expansive force of this heated air drives the working piston up, and with it the supply piston. During the ascent the air above the supply piston which is compressed before it passes through a communicating pipe into the working cylinder, and receiving an accession of heat keeps up the ascensional force. When the pistons have reached their highest point, a valve is opened by the machine, which establishes a free communication between the compressed and heated air under the working piston and the external air; it flows out, and the two connected pistons descend by their own weight.

It is to be observed, however, that the mechanical effect of this descending weight is but a compensation for the diminution of mechanical effect produced by the same weight in the ascent, and that the weight of the pistons therefore forms no part of the real motive power of the engine.

Confining our attention to the pair of double cylinders posited on either side of the main shaft, in the vacant space between the working and supply cylinders is placed a horizontal working beam, turning upon a shaft lying between the two double cylinders. One of the supply pistons is connected with one end of this working beam and the other with the other end; by means of links and connecting rods: and so, by the alternate action of the two working pistons, a reciprocating movement is communicated to the working beam.

It will be seen therefore, that one double cylinder, with the necessary appurtenances, constitutes a single acting engine, and that each contiguous pair of double cylinders, standing on either side of the main shaft, by the connection of their pistons with the opposite ends of a working beam, form a double acting engine; that they accomplish the same end as one double acting steam engine.

The shaft of the paddle wheels of the Ericsson is, accordingly driven by two double acting engines; one before and the other abaft the shaft. Each of these engines has its separate working beam. The power is transferred from each of these working beams to the shaft, (which, it is to be observed, is considerably elevated) by means of a connecting rod passing from the nearer end to the crank of the paddle-shaft. The two connecting rods are attached to the same crank-pin; and the relative position of the shaft and working beams is such that each of the connecting rods has a mean deviation of about 45° from the vertical position, and when one rod is passing the dead centre the other is acting upon the shaft with the maximum leverage.

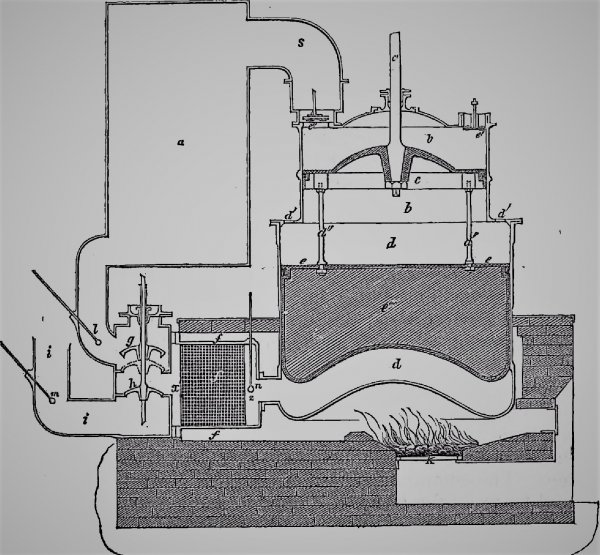

From what has been stated, it will be seen that in studying the essential theory of the new engine, we may confine our attention to one of the double cylinders with its accompanying mechanical arrangements, which taken together form one single acting engine. The essential parts of this engine are shown in the annexed diagram, which is a copy of Ericsson's representation of the stationary engine (Reduced from a plate in Appleton's Mechanics Magazine for February.)

The Caloric Engine description

These are, respectively, the double cylinder, with the pistons and piston rods ; the furnace ; a large vessel, communicating by pipes with the top of the supply cylinder and the bottom of the working cylinder, called the Receiver; and a piece of apparatus placed in the lowermost of these pipes, called the Regenerator.

The working piston in the engines of the Ericsson, has a diameter of 14 feet, and the supply piston a diameter of 11 feet 5 inches. The ratio of the areas of these pistons, and therefore also the ratio of the volumes of the two cylinders is as 3 to 2. The working piston is six feet deep, and concave underneath to fit the cylinder-bottom. The top and bottom, as well as the sides, are of iron, but the space between them is filled with gypsum and charcoal, non-conductors of heat. The packing of the piston is at the top.

The working cylinder is of necessity prolonged six feet below the position of the top of the piston when at its lowest point, thus forming a large vessel, called the heater, or heating chambers into which the air passes from the receiver. By this arrangement the packing at the top of the piston never comes into contact with any portion of the cylinder that is touched by the hot air.

The grate of the furnace is five feet below the apex of the dome-shaped cylinder-bottom. Anthracite coal is used, and acts by its radiant heat alone. The supply cylinder is merely a great condensing air-pump, which forces fresh air into the receiver, to be thence transmitted to the heating chamber under the working piston.

The supply piston is furnished with thirty-six self-acting valves, Which open upwards, and through which the air is admitted into the cylinder in the descending stroke of the piston. During the ascending stroke these valves remain closed, and the compressed air opens another set of valves at the top of the cylinder, and flows along the connecting pipe into the receiver. These two sets of valves may be called respectively, the outlet and the inlet valves.

The valve arrangement represented in the diagram is a little different; both the outlet and inlet valves are at the top of the cylinder. e' is an inlet, and e" an outlet valve. The air-receivers of the four double cylinders communicate with each other by connecting pipes, and thus form, in connection with the several communicating pipes, one common receiver, of so large a size, that, as it is asserted, the elastic force of the compressed air remains very nearly the same, in the working of the engine.

This receiver is provided with a guage. The communications between the receiver and the heater, and between the heater and the external air are closed by two puppet-valves. These valves are shown in the diagram at g and h. The one I will call the upper, and the other the lower valve. The thermometers at l, n, m, serve to indicate the temperature of the entering and escaping air. When the working piston reaches its lowest point, that is, is nearly in contact with the cylinder bottom, the upper valve is opened by the machine, the compressed air rushes from the receiver, through the regenerator into the space underneath the working piston, and the piston is forced up.

At two-thirds of the stroke this valve is closed, and the heated air acts expansively to the end of the stroke. The lower valve is now opened, and the same body of air escapes through it into the vertical pipe i, which communicates with the external air; passing again through the regenerator, on its exit.

The Regenerator is an admirable contrivance of Captain Ericsson's for abstracting the heat, or the greater portion of it, from the escaping air and restoring it again to an equal body of air entering the cylinder, to repeat the work performed by the air which has just escaped; that is, for employing the same amount of heat over and over again.

The regenerator consists of a large number of disks of wire-netting, placed side by side, and in a vertical position, in a marginal frame by which they are held very neatly in contact with each other, (see the diagram.) Each disk is six feet high and four feet broad, the wire of which it is made is 1/16th of an inch in diameter, and there are tens of thousands of minute meshes in the whole extent of the disk. The number of meshes in all the disks, added to the equal number of interstitial spaces between the disks, make up, it is stated, over 20 millions of minute cells through which the air passes and repasses, on its way to and from the working cylinder. In this way it is brought into contact with several thousand square feet of metallic surface, and parts with or imbibes heat almost instantaneously.

It is stated that Captain Ericsson estimates the time occupied by a particle of air in traversing the regenerator at about 1/30th of a second, and that this small interval of time suffices for the transfer of some 400° of heat from the escaping air to the wire, or from the wire to the entering cold air. The clear opening for the passage of the air through the regenerator is about twelve square feet.

We are told that the escape or waste air deposits all of its heat, with the exception of about 30°, in the regenerator, the thermometer at m never standing more than 30° higher than that at l. Ericsson estimates that in the case of the stationary engine, the amount of fuel wasted in the process of transfer, was only two ounces of coal per hour per horse-power, while the amount wasted by the radiation of the heated parts was about nine ounces per hour per horse-power, and the entire consumption about 11 ounces. (See last number of this Journal, p. 286.) But it should be observed that his calculation involves the supposition that the estimated horse-power (60) was realized in the actual working of the engine. We shall be better able to judge of the probability of this, after we have considered the details of the performance of the engines of the Ericsson.

After the engine has got into full operation, and the regenerator has reached its normal condition, there is a great difference between the temperatures of the inner and outer surfaces of the regenerator. We are told that in the case of the regenerator of the stationary engines this difference was never less than 350°. The explanation is found in the fact that the heated air, on its escape through the regenerator, must undergo a continual diminution of temperature, as it parts with its heat to the successive disks of wire-netting, and on the other hand the entering cold air, on passing through the successive disks, which are of a higher and higher temperature, will tend to lower the temperature of each one of these disks, and at the same time to increase the difference of temperature between the outer and inner surfaces of the regenerator, and thus to compensate for the tendency to equilibrium of temperature produced by the flow of heat from the inner towards the cooler outer surface.

For, while it will reduce the temperature of the outer surface, if the regenerator has sufficient thickness, nearly to an equality with the temperature of the external air, the inner surface being exposed towards a highly heated enclosure will be less affected. It is to be observed that the temperature of the external surface of the regenerator cannot at any time be greater than that of the air escaping through the pipe i, and that the temperature of the internal surface can never be less than that of the air issuing from this surface, on its passage into the working cylinder, or rather, heating chamber.

The preparation necessary for starting the engine consists in "keeping up a slow fire in the furnaces, for about two hours, until the various parts contained within the brick work shall have become moderately heated, and then charging the receiver with air by means of a hand-pump," until the guage shows a pressure of about eight pounds above that of the external air. The upper valve, g, is then opened by a starting bar, and the compressed air flows into the working cylinder, and begins the work of raising the piston.

We are now prepared to inquire into the

Theory of the motive power of the engine

I will first state a few principles which it is important should be kept in view.

-

The expansive force of the heated air under the working piston must be somewhat less than that of the compressed air in the receiver ; otherwise the air in the receiver would have no tendency to flow from it into the heating chamber. The difference may not amount to more than a few ounces; it depends upon the obstructions that exist to the free flow of the air and the relative size of the aperture of communication and heating chamber.

-

When the air is flowing from the supply cylinder into the receiver its elastic force must exceed that of the air in the receiver; for the additional reason, beside that just stated, that the valves in the supply-piston would close if no such difference of pressure existed.

In seeking to determine the power of the engine I shall however disregard the inequality of pressure and suppose the expansive force of the air to be the same in the working and supply cylinders as in the receiver, so long as the communications between them are open. -

Since the two connected pistons are of unequal size, and the elastic force of the air pressing upon them the same or nearly the same, the entire upward pressure exceeds the downward pressure, and the two pistons are urged up with a force equal to the difference of these pressures. This statement is here made with respect to the actual pressures subsisting when the communications are open. We shall see hereafter that it might also be made in regard to the mean effective pressures throughout the stroke.

-

In the engines of the Ericsson the cut off is introduced at the 2/3 stroke, and therefore the space underneath the working piston into which the air is admitted from the receiver, before the cut off valve is closed, is equal in volume to the interior of the supply cylinder. It will soon be seen that this is in accordance with a general principle, the adoption of which is essential to the most efficient operation of the present form of engine.

- When the engine has reached its permanent working state the quantity of air admitted into the working cylinder each upward stroke of the piston, cannot exceed the quantity forced into the receiver, from the supply cylinder, during the same interval. In fact it must be less, by reason of the waste from leakage and clearance

Now it will be perceived that if this quantity of air, after being admitted into the working cylinder, as just supposed, retained the same temperature, its elastic force would be the same as that of the external air (15 lbs. say, per square inch); since the same quantity originally filled the supply cylinder, at this pressure. But if we suppose its temperature to be elevated 480°, or thereabouts, by the heat derived from the regenerator and the heating chamber, its elastic force would be doubled, or amount to 30 lbs. per square inch.

To realize this supposition the compressed air in the receiver must therefore have an expansive force of over 30 lbs., or 15 lbs. above the atmospheric pressure. If the working temperature in the lower cylinder were 384° above the temperature of the external air instead of 480°, then the pressure in that cylinder, and of necessity therefore in the receiver, would be 12 lbs. above the atmospheric pressure, (i. e. 384/480ths of 15 lbs.) It will be seen then that the working pressure in the receiver and the working temperature in the principal cylinder are necessarily connected together - that the one determines the other.

It is here supposed that there is no leakage or clearance, but the fact is otherwise; and therefore the quantity of air admitted into the working cylinder, each ascending stroke, is less than that which is expelled from the supply cylinder into the receiver.

If we suppose the pressure in receiver to be 8 lbs. above the atmospheric pressure, and that the leakage and clearance, at this pressure amounts to 1/4, then 3/4 of the air furnished by the supply cylinder will enter the working cylinder, and its elastic force, for the 2/3 stroke, would be reduced to 11 1/4 lbs. (3/4 of 15 lbs.), by the expansion, if the temperature remained unchanged, but the 480° of additional heat will augment this to 22 1/2 lbs., or 15 lbs. + 7 1/2 lbs.

Now 8 lbs. above the atmosphere, is the actual working pressure of the engines, we may conclude therefore, that if the working temperature is 480° above the atmospheric temperature or a little less, the waste from leakage and clearance, during the double strokes, must amount to nearly 1/4.

The actual working temperature is undoubtedly less than this, but how much I have not been able to ascertain with certainty. The actual leakage is therefore less than 1/4 but its exact amount cannot at present be determined.

According to the newspaper accounts the working temperature, on the trial trip, was about 450°, or 418° above the temperature of the air (taken at 32°). This would make the waste, from leakage and clearance, about 1/5. It undoubtedly lies between 1/4 and 1/5.

Working at a given temperature, and with a given cut off, the leakage will determine the working pressure. To show this, suppose the elevation of temperature to be 480°, and the leakage 1/4 at a pressure of 8 lbs., shown by the receiver-guage ; then at 12 lbs. pressure the leakage, if we disregard the clearance which is comparatively small, would be 3/8ths, and the elastic force of the air in the working cylinder would be reduced from 7 1/2 lbs. to 3 3/4 lbs.

If the communications remained the same, so great a difference of pressure between the receiver and cylinder could not be realized; an additional quantity of air would flow out of the receiver, and this would go on for each successive stroke until the pressure in the receiver was reduced to 8 lbs. or thereabouts, when the pressure in the cylinder would be 7 1/2 lbs., and the engine would be nearly in its permanent working condition.

From this cause, (viz. the leakage,) mainly, as it would seem, the expected pressure of 12 lbs. has not been obtained in the working of the engines of the Ericsson. This is in fact the reason assigned by the builders of the engines, for the fact that no higher pressure than 8 lbs. has yet been realized.

There is another mode of presenting the theory of the motive power of the caloric engine. Suppose that the constant pressure in the receiver is 15 lbs. + 15 lbs. On this supposition air will begin to pass from the supply cylinder into the receiver, at the end of the 1/2 stroke, or thereabouts, and will continue to flow to the end of the stroke, at a pressure a little above this. At the end of the 1/2 stroke of the supply piston the body of air which originally filled the supply cylinder at 15 lbs. pressure, will oc¬cupy one-half the space at 30 lbs. pressure.

Now, while the communication between the receiver and the working cylinder continues open, that is during the 2/3 stroke, if we disregard the leakage, &c., the same quantity of air, at the same pressure of 30 lbs., will flow from the former to the latter. It is capable of filling a space equal to one-half of the supply cylinder, or what amounts to the same, one-third of the working cylinder, at the same temperature, without any change of pressure; therefore in expanding to fill two-thirds of the working cylinder its expansive force will be reduced to 15 lbs. To compensate for this it is only necessary that its temperature, as fast as it flows in, should be elevated 480°, when its expansive force will be retained at 30 lbs.

A similar explanation may be given for any other supposed pressure and temperature, and the question of the leakage may be considered from this point of view.

It has been stated that the cut off, whatever may be the relative size of the two cylinders, should be so adjusted that the portion of the working cylinder into which the air is admitted while the valve remains open, will be equal in volume to the whole supply cylinder.

To show this, we will at first leave the leakage out of view, and denote the fractional part of the stroke answering to the cut off supposed, (in the present engines 2/3) by a, and a larger fraction of the stroke, answering to a different cut off, by b. Let b be n times greater than a. Now, if we conceive the fractional cut-off-stroke to be less than a, the actual working pressure remaining the same, the mean effective pressure, for the whole stroke, will be less than when a is used.

If, on the other hand, it be made greater, (as b=na), the body of air which originally filled the supply cylinder, at 15 lbs. pressure and 32° temperature, on entering the working cylinder, will expand n times, and its, working force will be (15/n) x 2 (supposing working temperature to be 480°+32°); whereas, for the cut off a the force will be 15x2, and in the subsequent expansion from a to b, the mean force throughout the fractional stroke b will be greater than (15x2)/n since this will be the actual force after the expansion to b.

The same will be true if we take the leakage into account; for suppose the leakage to reduce the pressure of the air that fills

a, before it is heated, to 15/m, then when heated 480° the pressure becomes (15/m)x2, which we will put equal to k. Now, if we suppose, as before, the cut off to be increased from a in b, the force k will be reduced to k/n; but the mean effective pressure for the same fractional stroke b, when the cut off a is used, will be greater than this, and the actual pressure after the expansion to b, will be k/n. So that the constant pressure for the b cut off is equal to the pressure for the a cut off reduced by the expansion to b.

It may be well to inquire, in this connection, into the proper relative size to be given to the supply and working cylinders to obtain the greatest amount of motive power from the engine. Let A = area of supply piston, and w = ratio of working to supply piston; then, by what we have seen, the portion of the stroke during which the air is flowing into the working cylinder, and

acting with its full constant pressure is equal to 1/w.

Calling this pressure per square inch, P, the following proportion gives us the mean effective pressure (p) on working piston, for the whole stroke, viz., w : hyp. log. w+1 ::P :p = (P log.w + P)/w. The mean effective upward pressure upon the whole piston will, therefore bet expressed by (P log.w + P)/w x Aw, or P.A log.w + P.A.

The, downward pressure on the working piston = 15 lbs. x.Aw, and hence the resulting effective pressure P.A log.w + P.A - 15Aw.

With the aid of the differential calculus, we find this expression to be a maximum when w = P/15 (more accurately P/14.7); from which it appears that the engines will have the greatest possible power, at any given working pressure, when the cut off, taken inversely, and the ratio of the volumes of the two cylinders, are each equal to the working pressure per square inch, divided by the atmospheric pressure (15 lbs).

Accordingly the ratio of the bulks of the cylinders ought to vary with the working pressure used. When this pressure is 8 lbs. above the pressure of the atmosphere, the cubical content of the supply cylinder ought to be 648/1000 of that of the working cylinder, and the portion of the stroke from the commencement at which the air is cut off, the same. The actual ratio of the cubical contents of the cylinders of the engines of the Ericsson is 665/1000 (66/1000 nearly), and the fraction of the stroke at which the air is cut of is said to be about 63/100.

lf a pressure of 12 lbs. instead of 8 lbs. were used, the same ratio ought to be 55/100. This would make the radius of the working piston 15.4 feet. It was Ericsson's original design that it should be 16, feet.

Let us see now how the power of the engines of the caloric ship is to be determined.

Determining the power of the engine

The actual pressures upon the two pistons are the same, or nearly the same, while the communications are open; the pressure on the top of the supply piston begins at 15 lbs., becomes 8 lbs. + 15 lbs. at the 2/3 stroke from the end (more accurately 65/100), and continues the same to the end of the stroke. The air is shut off from the working cylinder at the same fractional part of the stroke, and acts expansively to the end of the stroke. The mean effective pressure per square inch, for the whole stroke, is then the same upon both pistons.

It may be found in the usual manner, by the use of hyperbolic logarithms.

Multiply this, diminished by 15 lbs., into the difference between the areas of the two pistons; expressed in square inches, and again into the velocity of the piston per minute, and divide the product by 33,000, and the result will be the horse-power of one of the engines.

But it is to be observed that the result thus obtained will be somewhat too large, for the following reasons.

-

The actual pressure in the supply cylinder is greater than the pressure in the receiver (8 lbs.), and the actual pressure in the working cylinder is less than this.

-

During the 1/3 stroke from the commencement, the outlet valves at the top of the supply cylinder remain closed, and consequently the expansive force of the air in the receiver must be somewhat reduced by the flow of air from it into the working cylinder.

- After the cut off valve is closed, the elastic pressure of the air in the working cylinder during the remaining 1/3 stroke, must be diminished somewhat by leakage. The effect of this leakage has not hitherto been taken into as count.

Performance

There have been two trial trips of the Ericsson, in the New York harbor and bay, and the ship has subsequently made a successful trip to Alexandria and back. On the first occasion, only the inventor, owners and crew were present. The performance on the occasion of the second trip (Jan. 11th, 1853) was witnessed by the members of the New York press, and a few other gentlemen, present by invitation.

The results of the trip have been published in all the New York papers, but the different accounts disagree very materially on most of the important points. By personal inquiry and by consulting the most reliable accounts I have endeavored to come as near to the truth as possible.

The following are the principal results:

- No. of revolutions of wheels per minute (according to Ericsson): 9 1/4

- No. of revolutions of wheels per minute (according to other most reliable authorities): 9

- Speed through the Water (according to Ericsson): 8 1/2 miles

- Speed through the Water (according to other authorities): 7 miles

- Working pressure in receiver, per square. inch: 8 lbs.

- Consumption of anthracite coal in 24 hours: 6 tons

The two estimates of the speed through the water are quite different, but the number of revolutions of the paddle wheels, as stated by different authorities, lies between 9 and 9 1/4.

The number of revolutions, about which there is but little disagreement, will enable us to obtain by calculation a pretty close approximation to the speed. For this purpose we have the following data. Diameter of the wheels from centre of pressure to centre of pressure, 30 3/4 feet; paddles 32 in number, on each wheel, and 10 1/2 feet long by 16 inches deep; dip of the wheels 44 inches.

The following quantities were obtained by calculation, viz : number of paddles in water, on each wheel, 7; immersed paddle surface on both wheels, 196 square feet; area of midship section, at 17 feet draft, 520 square feet; ratio of immersed paddle surface to area of midship section, 1 to 2.653; same for steamship Arctic, 1 to 1.662 (see Journal of Franklin Institute for Jan., 1853, No. 1, p. 33); slip of wheels of Arctic, 19.32 per cent. From which we find the slip of the wheels of the Ericsson, on the trial trip, to have been 24.4 per cent. The distance passed over by the centre of pressure of wheels was 9.88 miles per hour. Hence, allowing for the slip, the speed of the ship was 7.47 miles per hour. If we allow for the less oblique action of the paddles in the case of the Ericsson than in that of the Arctic, we find the speed to have been 7.57 miles per hour (the slip of the wheels being reduced to about 23.4 from this cause).

There is some little uncertainty with regard to the area of the midship section. Although I have not succeeded in obtaining the data necessary for an exact calculation of this element, the information furnished me in reference to the model of the Ericsson as compared with that of the steamers of the Collins line, has enabled me to approximate very nearly to a correct result.

The rule by which the calculation was made has been tested by trying it upon a large number of ships. It gives results, in almost every instance, a little too small; thus for the Arctic, the result is 662, and the true area is 685. The greater "dead-rise" of the Ericsson may diminish the area, as compared with the Arctic, some 30 square feet ; which would make it about 510 square feet. It in all probability, lies between 520 and 500.

If we take it at 500, the slip of the wheels comes out 23 per cent., and the speed of the ship 7.61 miles (If we take the number of revolutions of the paddle wheels at 91, the speed comes out 7.88 miles). In view of all that has now been stated, we may conclude that the average speed of the Ericsson through the water, on the trial trip, could not have exceeded 7 3/4 statute miles per hour; and was most probably about 7 1/2 miles.

Horse-power of the Ericsson's Engines developed on the trial trip

Horse-power of the Ericsson's Engines, developed on the trial trip.

Working pressure of air, 8 lbs. + 15 lbs. Supposing the cut off to be at 15/23 (=0.652) of the stroke, then the mean effective pressure, in each cylinder, would be 6.4 lbs.+ 15 lbs.; and the horse-power of both engines, calculated by the rule given on page 403, would be 311. If we take the cut off 63/100, as it is stated to be in some accounts, then the mean effective press¬ure in the working cylinder we find to be 6.04 lbs. + 15 lbs., while that in the supply cylinder remains at 6.4 + 15. With these data the result obtained for the horse-power is 259.

For a mean effective pressure, in each cylinder, equal to 6 lbs. the result is 292; and for 6 1/2 lbs., it is 316.

The power developed by the engines on the trial trip, was undoubtedly less than the determination above obtained (311), for the reasons mentioned on page 403; we may safely conclude that it could not have exceeded 300 horses-power. It was probably less.

This is but one-half of the full power of the engines, according to Captain Ericsson's estimate. This estimate supposes a working pressure of 12 lbs. to be employed, whereas, by reason of leakage, &c., but 8 lbs. could be obtained. In fact, making the calculation on the supposition of a working pressure of 12 lbs., and taking the cut off at 2/3 stroke, neglecting also the clearance, which is not known, I find the horse-power of the two engines to 640. The allowance for clearance, and other causes of reduction which have been indicated (see p. 403), may well reduce this determination to 600.

The power, but for practical difficulties, may be indefinitely increased, by enlarging both cylinders, keeping their relative size the same.

It is stated that Captain Ericsson has fixed upon 12 lbs. as the highest limit likely to be practically reached in the working of caloric engines. This must be regarded as an indication either that it is not expected the leakage will be entirely stopped, or that it is supposed that it will not be regarded as safe and economical, to work at the high temperature of 500°, and upwards, necessary to double the expansive force of the air.

Consumption of Fuel, on trial trip, 6 tons of anthracite coal per day, or 560 lbs. per hour. This amounts to 1.87 lbs. per horse-power per hour. If the full power of the engines (600) were to be developed, the expenditure would be 0.93 lbs. per horse-power per hour. On the other hand, if we allow that the excess of pressure in the receiver over that in the working cylinder, on the trial trip, was 3/10 of a pound per square inch, and the excess of pressure in the supply cylinder over that in the receiver the same, we find that, with a cut off at 2/3, the horse-power developed could not have been more than 248. The expenditure of fuel, answering to this determination, would be 2.26 lbs. per horse-power per hour.